Threaded Rubber Joint Expansion Joint Union

Product Data

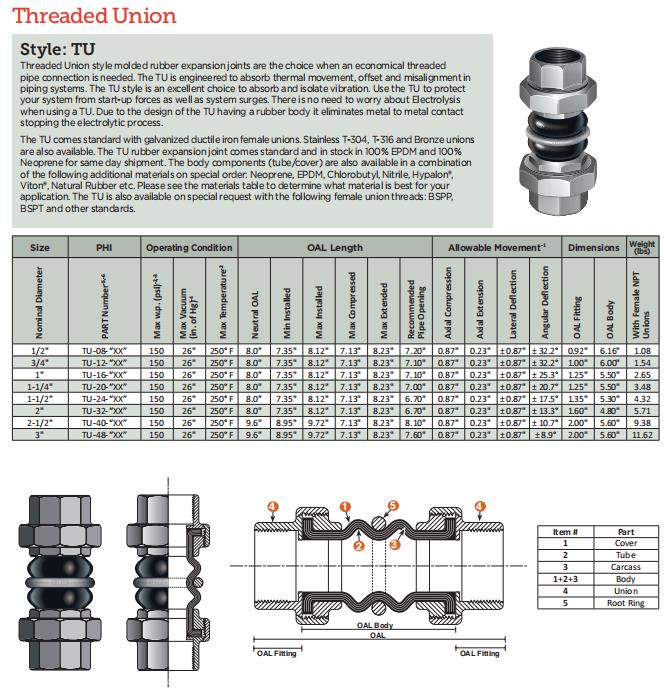

| SIZE | Operating Conditions | OAL Length | Allowable Movement-1 | Dimensions | Weight (LBS) | |||||||||||

| Nominal Diameter |

Max w.p. | Max Vacuum | Max Temperature-2 | Neutral OAL | Min Installed | Max Installed | Max Compressed | Max Extended | Recommended Pipe Opening | Axial Compression | Axial Extension | Lateral Deflection | Angular Deflection | OAL Fitting | OAL Body | With Female NPT Unions |

| (psi)-2,-3 | (in. of Hg)-4 | |||||||||||||||

| 1/2" | 150 | 26” | 250° F | 8.0" | 7.35" | 8.12" | 7.13" | 8.23" | 7.20” | 0.87" | 0.23" | ±0.87" | ±32.2° | 0.92" | 6.16" | 1.08 |

| 3/4" | 150 | 26” | 250° F | 8.0" | 7.35" | 8.12" | 7.13" | 8.23" | 7.10” | 0.87" | 0.23" | ±0.87" | ±32.2° | 1.00" | 6.00" | 1.54 |

| 1" | 150 | 26” | 250° F | 8.0" | 7.35" | 8.12" | 7.13" | 8.23" | 7.10” | 0.87" | 0.23" | ±0.87" | ±25.3° | 1.25" | 5.50" | 2.65 |

| 1-1/4" | 150 | 26” | 250° F | 8.0" | 7.35" | 8.12" | 7.13" | 8.23" | 7.00” | 0.87" | 0.23" | ±0.87" | ±20.7° | 1.25" | 5.50" | 3.48 |

| 1-1/2" | 150 | 26” | 250° F | 8.0" | 7.35" | 8.12" | 7.13" | 8.23" | 6.70” | 0.87" | 0.23" | ±0.87" | ±17.5° | 1.35" | 5.30" | 4.32 |

| 2" | 150 | 26” | 250° F | 8.0" | 7.35" | 8.12" | 7.13" | 8.23" | 6.70” | 0.87" | 0.23" | ±0.87" | ±13.3° | 1.60" | 4.80" | 5.71 |

| 2-1/2" | 150 | 26” | 250° F | 9.6" | 8.95" | 9.72" | 7.13" | 8.23" | 8.10” | 0.87" | 0.23" | ±0.87" | ±10.7° | 2.00" | 5.60" | 9.38 |

| 3" | 150 | 26” | 250° F | 9.6" | 8.95" | 9.72' | 7.13" | 8.23" | 7.60” | 0.87" | 0.23" | ±0.87" | ±8.9° | 2.00" | 5.60" | 11.62 |

Product Introduction

Threaded rubber expansion joint, also called spiral rubber expansion joint, is a common type of rubber expansion joint.

The thread rubber expansion joint has a thread shape and is mainly composed of inner rubber, reinforcement layer and outer rubber.

Its main characteristics are excellent chemical properties such as high temperature resistance, oil resistance, acid and alkali resistance, and easy installation, good sealing, and significant vibration and noise reduction functions.

Threaded rubber expansion joint can choose different rubber materials according to different media, such as EPDM, NBR, CR, etc.

Size

Dimensions: The inner diameter ranges from DN15 to DN300, and the length ranges from 100mm to 400mm.

Pressure rating: Generally PN6, PN10, PN16, PN25, etc. Products with higher pressure ratings can be customized according to usage requirements.

Components

Threaded rubber expansion joint is generally composed of inner rubber, reinforcing layer and outer rubber. Among them, the inner rubber is usually made of acid alkali resistant and high-temperature resistant rubber materials, such as EPDM (ethylene propylene rubber); The reinforcement layer generally uses reinforcement bars wrapped around multiple layers of steel wire or polyester wire to increase its pressure resistance; The outer layer of rubber is usually made of high-quality rubber materials such as EPDM to improve its aging resistance, wear resistance, and sealing performance.

Application scope

The threaded rubber expansion joint is suitable for industrial pipeline systems and can be connected to various flanges. It is widely used in air conditioning and refrigeration, water supply and drainage, compressed air, oil and gas transmission systems.

1.HVAC system: including central air conditioning system, underfloor heating system, air handling system, etc.

2.Water supply and drainage system: including urban water supply pipelines, building internal water supply pipelines, sewage treatment pipelines, industrial wastewater pipelines, etc.

3.Compressed air system: includes equipment such as compressors, dryers, filters, and gas storage tanks.

4.Oil and gas transportation system: including long-distance pipelines for oil, natural gas, liquefied petroleum gas, and connecting pipelines between oil pumps and oil tanks at gas stations.

5.Other systems: can also be used in pipeline systems in fields such as chemical industry, food industry, pharmaceutical industry, papermaking industry, etc., to play a role in shock absorption, noise reduction, and compensation for pipeline deformation.

It should be noted that when selecting threaded rubber expansion joint, appropriate models and materials should be selected according to specific media, temperature, pressure and other parameters. Also, be careful to avoid excessive stretching or twisting. In addition, regular inspection and maintenance shall be carried out for the expansion joint to ensure its normal operation and extend its service life.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top