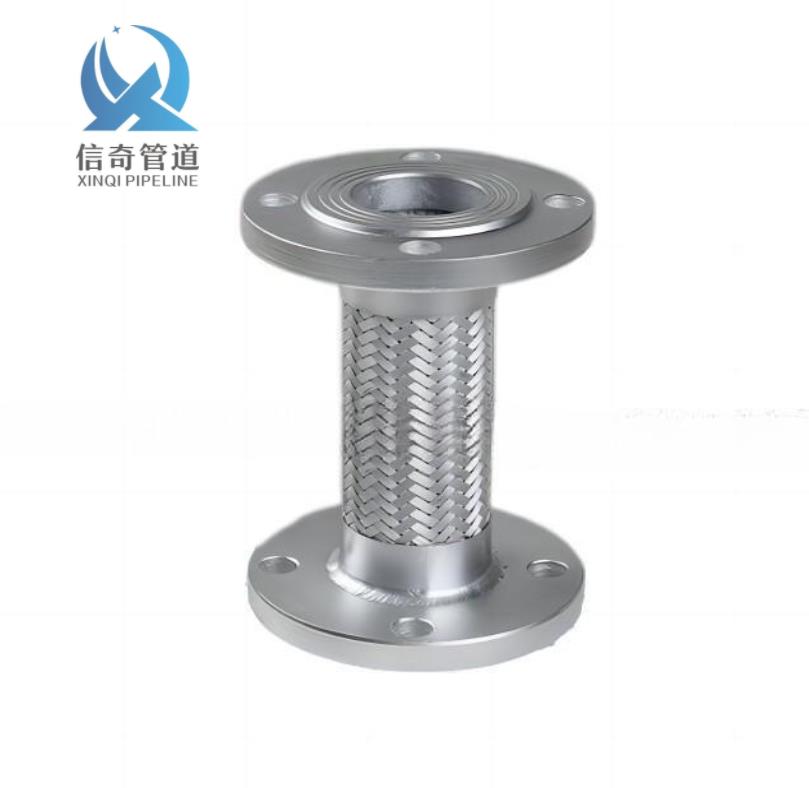

Stainless Steel DN32-DN2000 Large Diameter Universal Metal Bellows

Product Data

| Product Name | Large Diameter Metal Bellow | |||||

| Size Specification | DN32-DN2000 | |||||

| Type | Seamless | |||||

| Standard | ANSI | |||||

| Material Brand | Stainelss Steel SS316 SS304 SS321 SS904L | |||||

| Manufacturing Process | single ply ,double ply,multi plies | |||||

| Pressure | PN0.1Mpa-PN4.0Mpa | |||||

| Length | customized | |||||

| Application | Hydraulic Pipe, Fluid Pipe, Gas Pipe, Chemical Fertilizer Pipe, Oil Pipe, Structure Pipe, Boiler Pipe, Drill Pipe | |||||

| Bellows Parameters Table | |||||

| Specification | ID(d) | OD(D) | Wave thickness(t) | Layer Number(n) | Wave distance(q) |

| N10 | 10 | 16 | 0.12 | 2 | 2.5 |

| DN12 | 12 | 20 | 0.15 | 2–3 | 2.5 |

| DN16 | 16 | 25 | 0.15 | 2–3 | 3 |

| DN18 | 18 | 28 | 0.15 | 2 | 3 |

| DN22 | 22 | 32 | 0.15 | 2–3 | 3.5 |

| DN25 | 25 | 38 | 0.15 | 2–3 | 4 |

| DN28 | 28 | 40 | 0.15 | 2 | 3.5 |

| DN32 | 32 | 45 | 0.16 | 2–3 | 4 |

| DN35 | 35 | 50 | 0.2 | 2–3 | 5 |

| DN40 | 40 | 60 | 0.3 | 2–3 | 5 |

| DN50 | 50 | 70 | 0.3 | 2–3 | 5 |

| DN65 | 65 | 90 | 0.3 | 2–3 | 5.8 |

| DN80 | 80 | 105 | 0.35 | 2 | 7 |

| DN100 | 100 | 130 | 0.35 | 2 | 7.5 |

| DN125 | 125 | 157 | 0.4 | 2 | 11.5 |

| DN150 | 150 | 200 | 0.5 | 2 | 12 |

Product Introduction

Metal Bellows expansion joint (they are also called compensator ) are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints.

Metal Bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape (provided the material has not been stressed past its yield strength).

Features

1.Reasonable structure, good elasticity, large range of compensation pipeline and little counter force to the brackets of pipeline.

2.Shock absorption and noise decrease, heat and dust insulation, environmental protection and simple structure bracket.

3.The displacement can be deflected to prevent damage caused by subsidence of connected brackets and equipment base. It can adapt itself to the centrifugal difference of pipeline installation to provide convenience to installation and maintenance.

4.Good resistance to milling, heat, aging and corrosion and long service life.

5.Little resistance and little weight. Each performance is better than the compensation device of other materials.

6.The temperature range of media is wide:-40-300°c

Advantages and performance

1. Strong resistance to external pressure: The outer wall is in a circular and corrugated structure, greatly enhancing the ring stiffness of the pipe, thereby enhancing the resistance of the pipeline to soil loads. In terms of this performance, metal large-diameter corrugated pipes have obvious advantages compared to other pipes.

2. Low engineering cost: Under equal load conditions, metal large-diameter corrugated pipes only require a thinner pipe wall to meet the requirements. Therefore, compared to solid wall corrugated pipes of the same material specification, it can save about half of the raw materials, so the cost of metal large-diameter corrugated pipes is also lower. This is another prominent feature of this pipe material: easy construction. Due to the light weight of the metal large diameter corrugated pipe, it is easy to handle and connect, making construction fast and maintenance work simple. In situations where the construction period is tight and the construction conditions are poor, its advantages are more obvious.

3. Good low-temperature resistance and impact resistance: The embrittlement temperature of metal large diameter corrugated pipes is -70 ℃. Under general low temperature conditions (above -30 ℃), special protective measures do not need to be taken during construction. Winter construction is convenient, and metal large-diameter corrugated pipes have good impact resistance.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top