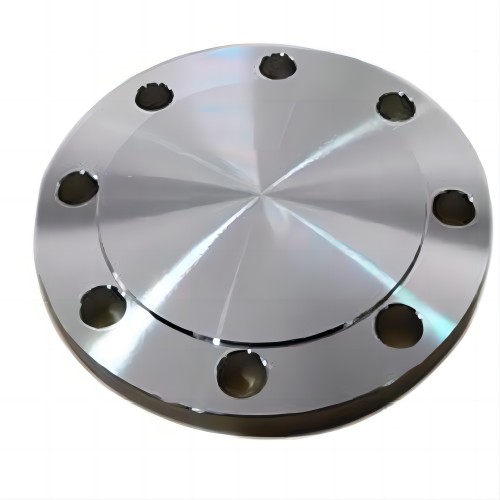

Stainless Steel Blind Flange Blank ANSI JIS BS DIN GOST 1.4301/1.4307

Product Data

| Product Name | Stainless Steel Blind Flange | |||||||

| Size | 1/2″-48″ DN15-DN1200 | |||||||

| Specification | Class150-Class2500;PN2.5-PN40 | |||||||

| Standard | ANSI B16.5,EN1092-1, SANS 1123, JIS B2220,JIS B2238 DIN2527, GOST 12836,etc. | |||||||

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. | |||||||

| Material | Stainless steel: F304/304L, F316/316L, 904L, and etc. | |||||||

| Facing | RF; RTJ; FF; FM; M; T; G; | |||||||

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. | |||||||

Product Introduction

Blind flange, also known as a blank flange, is a type of flange without a hole in the middle, which is a solid disk that can be used to seal pipeline openings.

The function of the blind flange is the same as that of the head and pipe cap, but the difference is that the blind seal is a detachable sealing device, and the seal of the head is not prepared to be opened again. On the one hand, blind flanges are more flexible in operation.

There are many types of sealing surfaces for blind flanges, including flat, convex, concave convex, tenon groove, and ring connection surfaces.

In terms of materials, blind flanges actually include carbon steel, stainless steel, alloy steel, copper, aluminum, PVC, and PPR. Carbon steel and stainless steel have the highest usage rate among them.

Stainless steel blind flange is a common pipe connection accessory used to close non operational or temporarily closed pipe openings in pipeline systems. It usually consists of a flat circular blind plate body and protruding connecting bolt holes.

Stainless steel blind plates are mainly made of stainless steel materials, with common stainless steel materials such as 304, 316, 321, etc.

Application

Stainless steel blind plates are mainly used for sealing operations in industrial pipeline systems, such as pipeline maintenance, equipment maintenance, system testing, etc. It can seal the pipeline mouth to prevent medium leakage.A

Advantages and Disadvantages

Advantages:

1. Strong corrosion resistance: stainless steel blind flange has good corrosion resistance and can be used stably in various liquid media and gas environments for a long time.

2. Good high-temperature resistance: The stainless steel blind flange can withstand high temperature environments and has good high-temperature resistance performance, suitable for high-temperature process pipeline systems.

3. High strength: The stainless steel blind flange has high strength and can withstand high pressure and high loads.

4. Long service life: Stainless steel blind flange has good corrosion resistance and can be used stably for a long time, with a long service life.

5. Easy installation: The installation process of stainless steel blind flange is simple and convenient, without the need for special tools, making it easy to quickly disassemble and replace.

Disadvantages:

1. High price: The production material cost of stainless steel blind flange is relatively high, resulting in its relatively high price.

2. Long manufacturing cycle: the manufacturing process of stainless steel blind flange is complex and the Makespan is long, which may take a long time to manufacture and deliver.

3. Limited by material selection: The selection of stainless steel blind flanges is limited by the type and specification of stainless steel, and may not be able to meet certain special needs of pipeline systems.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top