Sabs 1123 Basic Information

Picture Presentation

Product Description

The full name of neck flat welding flange is neck flat welding steel pipe flange. This type of flange is designed to extend steel pipe, fittings, and other components into the flange itself. It is connected to equipment or pipes through fillet welds, providing a safe and stable joint. Necked flat weld flanges are particularly useful in applications where high pressure and high temperature conditions are prevalent.

SABS 1123 is a South African Bureau of Standards specification that outlines requirements for steel pipe flanges. These flanges are commonly used in various industries, including petrochemical, oil and gas, and water treatment. This standard ensures that flanges meet specific criteria for materials, dimensions and performance, thereby guaranteeing reliability and safety in their application.

Neck flat weld flanges are engineered to meet the stringent requirements of a variety of industrial applications. It is made from top quality materials ensuring durability, strength and longevity. This flange is particularly suitable for applications where a strong and leak-proof connection is critical.

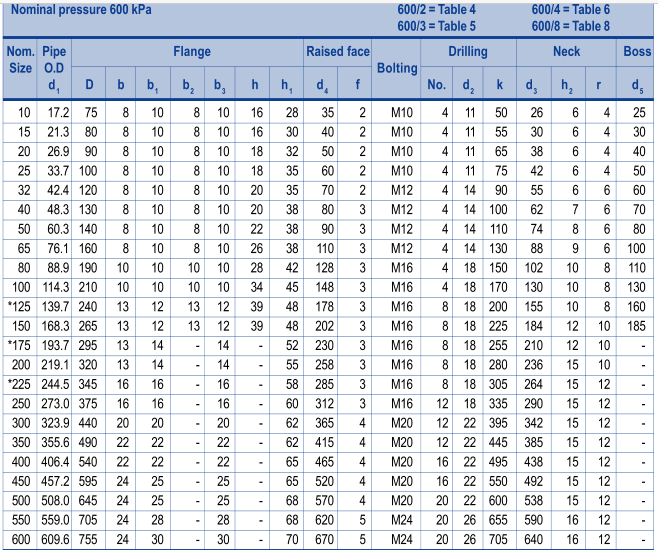

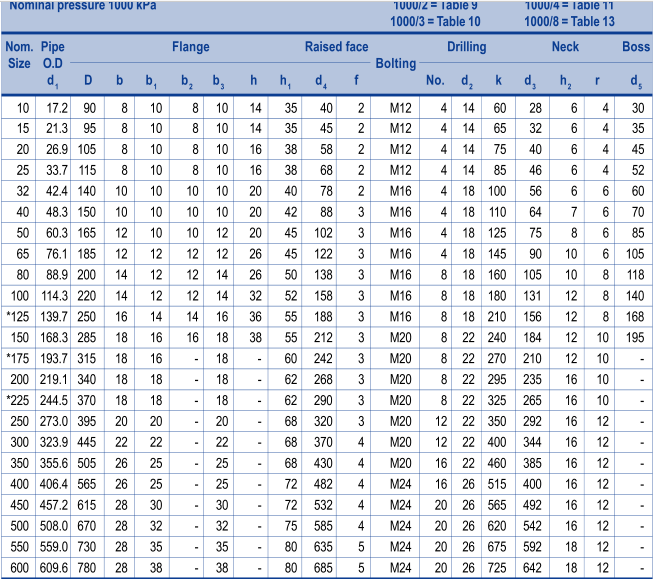

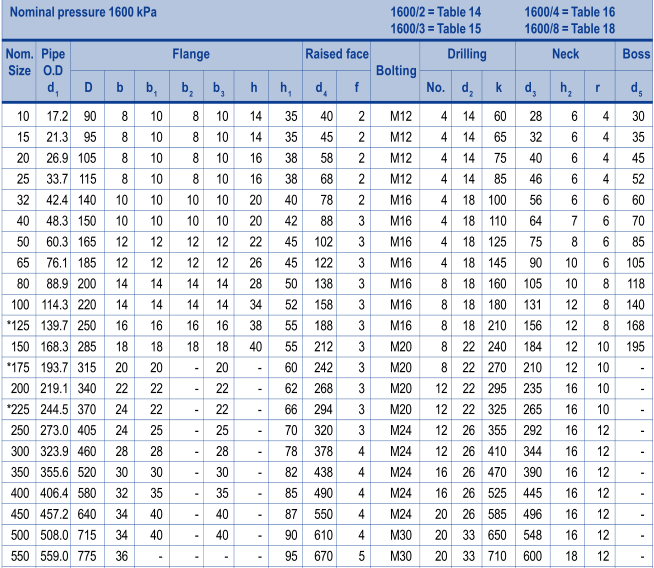

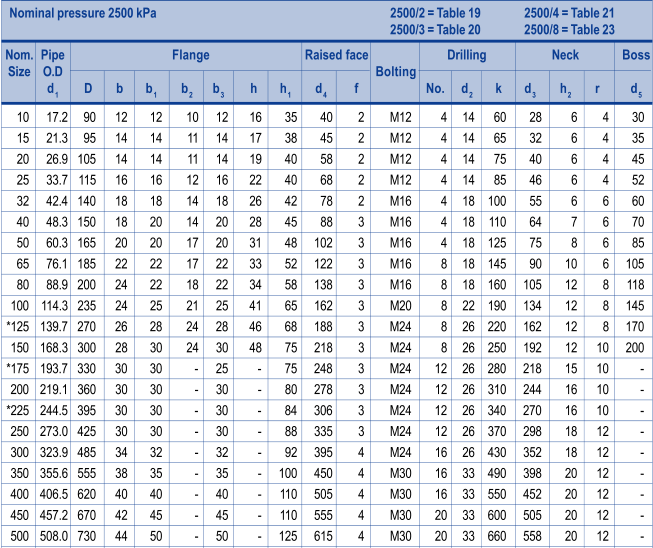

Diameter range: DN10~DN600

Scope of application

PN series PN2.5~PN40; Class series Class150~Class1500

Flange material: carbon steel, 304, 316, 304L, 316L.

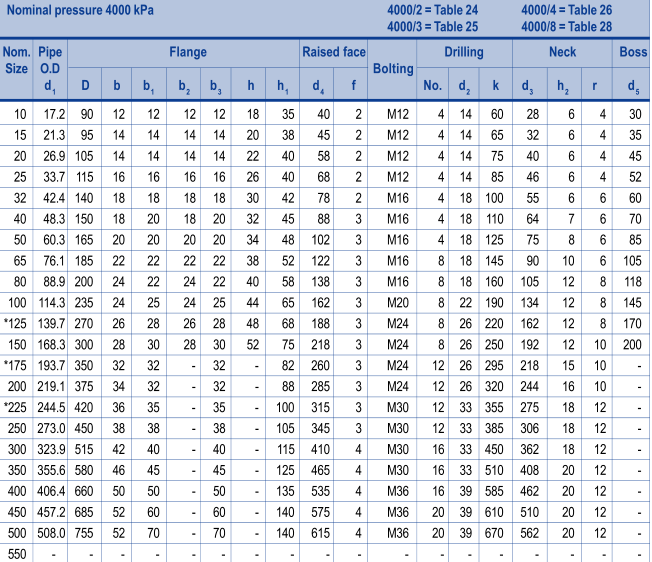

Data Reference

Main feature

1. Material: The flange is made of high-quality steel to ensure durability and corrosion resistance. This is especially important in harsh industrial environments where flanges are exposed to a variety of chemicals and extreme temperatures.

2. Dimensional Accuracy: The SABS 1123 standard specifies the precise dimensions of the flange to ensure a perfect fit with other components. This precision minimizes the risk of leaks and increases the overall efficiency of the piping system.

3. Easy to Install: The necked flat welding flange is designed for easy installation. Fillet welds provide a strong and secure connection, reducing the time and effort required for assembly.

4. VERSATILITY: These flanges are suitable for a wide range of applications from low pressure systems to high pressure environments. Their versatility makes them a popular choice across a variety of industries.

5. Testing and Certification: Our company uses comprehensive testing methods to ensure that each flange meets the SABS 1123 standard. This rigorous testing ensures that flanges are safe and reliable for use in critical applications.

Advantage

1. Strength and Durability: Neck flat weld flange offers excellent strength and durability for high pressure applications. Fillet welds provide strong connections that can withstand significant stresses and strains.

2. Easy to Install: Due to their simple design, these flanges are relatively easy to install. The welding process is simple, reducing the time and effort required for installation.

3. VERSATILITY: Necked flat weld flanges are versatile and can be used in a variety of applications from industrial piping to water treatment facilities. Their adaptability makes them a popular choice among engineers and technicians.

Shortcoming

1. Welding Requirements: While the welding process is simple, it does require skilled labor to ensure a correct and secure connection. Inadequate welding can lead to leaks and other problems.

2. Inspection and Maintenance: Regular inspection and maintenance are necessary to ensure the integrity of the weld. This increases the overall cost and effort required to maintain the system.

3. Material Cost: The materials used in necked flat weld flanges, especially those that comply with SABS 1123 standards, may be more expensive than other types of flanges. This may impact the overall budget of the project.

Why choose our

1. Powerful Technical Power: Our team of experts ensures that every product meets the highest quality and performance standards.

2. Complete Production Equipment: We utilize state-of-the-art machinery to produce flanges that are both durable and precise.

3. Perfect testing methods: Each flange is rigorously tested to ensure it meets all relevant standards, including SABS 1123.

FAQ

1. What material do you use for your necked flat welding flange?

We use high-quality steel to manufacture our necked flat weld flanges, ensuring durability and corrosion resistance.

2. Do your flanges meet international standards?

Yes, our flanges comply with SABS 1123 and other international standards, making them suitable for global applications.

3. How to install neck flat welding flange?

Installation involves extending steel pipe or fittings into the flange and securing with fillet welds. This method ensures a secure and leak-proof connection.

4. Can I customize the size?

Absolutely! We offer custom sizes to meet your specific requirements. Please contact our sales team for more information.

5. Which industries use neck flat welding flanges?

These flanges are widely used in industries such as oil and gas, chemical processing, and water treatment due to their reliability and strength.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top