Professional China Pipeline Compensation - Carbon Steel Seamless Bw Fittings Elbow 90 Deg – Xinqi

Professional China Pipeline Compensation - Carbon Steel Seamless Bw Fittings Elbow 90 Deg – Xinqi Detail:

Seamless elbow is a kind of pipe fitting used for pipe turning. Among all the pipe fittings commonly used in the pipe system, the proportion is the largest, about 80%. Generally, different forming processes are selected for elbows with different materials and wall thicknesses. The commonly used seamless elbow forming processes of manufacturers include hot pushing, stamping, extrusion, etc

Seamless Elbow Classification

Seamless elbow is also called seamless steel pipe elbow. Due to different manufacturing processes, seamless elbow fittings can be divided into hot extruded seamless elbow fittings and cold extruded seamless elbow fittings.

Executive standards: GB/T12459-2017, GB/T13401-2017

Forming Method of Seamless Elbow

1. Forging method: stretch the end or part of the pipe with a swaging machine to reduce the outer diameter. The commonly used swaging machines are rotary, connecting rod and roller.

2. Rolling method: generally no mandrel is used, and it is suitable for the inner circular edge of thick wall pipe. The core is placed in the pipe, and the periphery is pushed with a roller for processing the round edge.

3. Stamping method: expand the pipe end to the required size and shape with a tapered core on the punch.

4. Bending forming method: there are three commonly used methods, one is called stretching method, the other is called stamping method, and the third is roller method, which has 3-4 rollers, two fixed rollers, and one adjustment roller. Adjust the fixed roller pitch. The finished pipe fittings are bent.

5. Bulging method: one is to place rubber in the tube and compress it with a punch to make the tube bulge into shape; The other method is hydraulic bulge forming. Fill the middle of the pipe with liquid, and the liquid pressure will bulge the pipe into the desired shape. This method is mostly used in the production of corrugated pipes.

Summary of Advantages

Hygienic, non-toxic, light weight, good heat resistance, good corrosion resistance, good thermal insulation, good impact resistance, and long service life.

1. Hygienic and non-toxic: the material is completely composed of carbon and hydrogen, without adding any toxic heavy metal salt stabilizer, and the hygienic performance of the material has been tested by the national authoritative department.

2. Light weight: the density of stamping elbow is 0.89-0.91g/cm, which is only one tenth of that of steel pipe. Because of its light weight, it can greatly reduce the transportation cost and the construction intensity of installation.

3. Good heat resistance: when the working water temperature is 70 ℃, the softening temperature is 140 ℃.

4. Good corrosion resistance: except for a few hydrogenating agents, it can resist the corrosion of various chemical media, and has excellent acid, alkali, corrosion resistance, no rust, no corrosion, no bacteria, no electrochemical corrosion.

5. High impact resistance: because the unique impact strength performance is significantly improved compared with other solid wall pipes, its ring stiffness is 1.3 times of the solid wall.

6. Long service life: under the rated service temperature and pressure, the pipe has a service life of more than 50 years, and is UV and radiation resistant, so that the product will never fade.

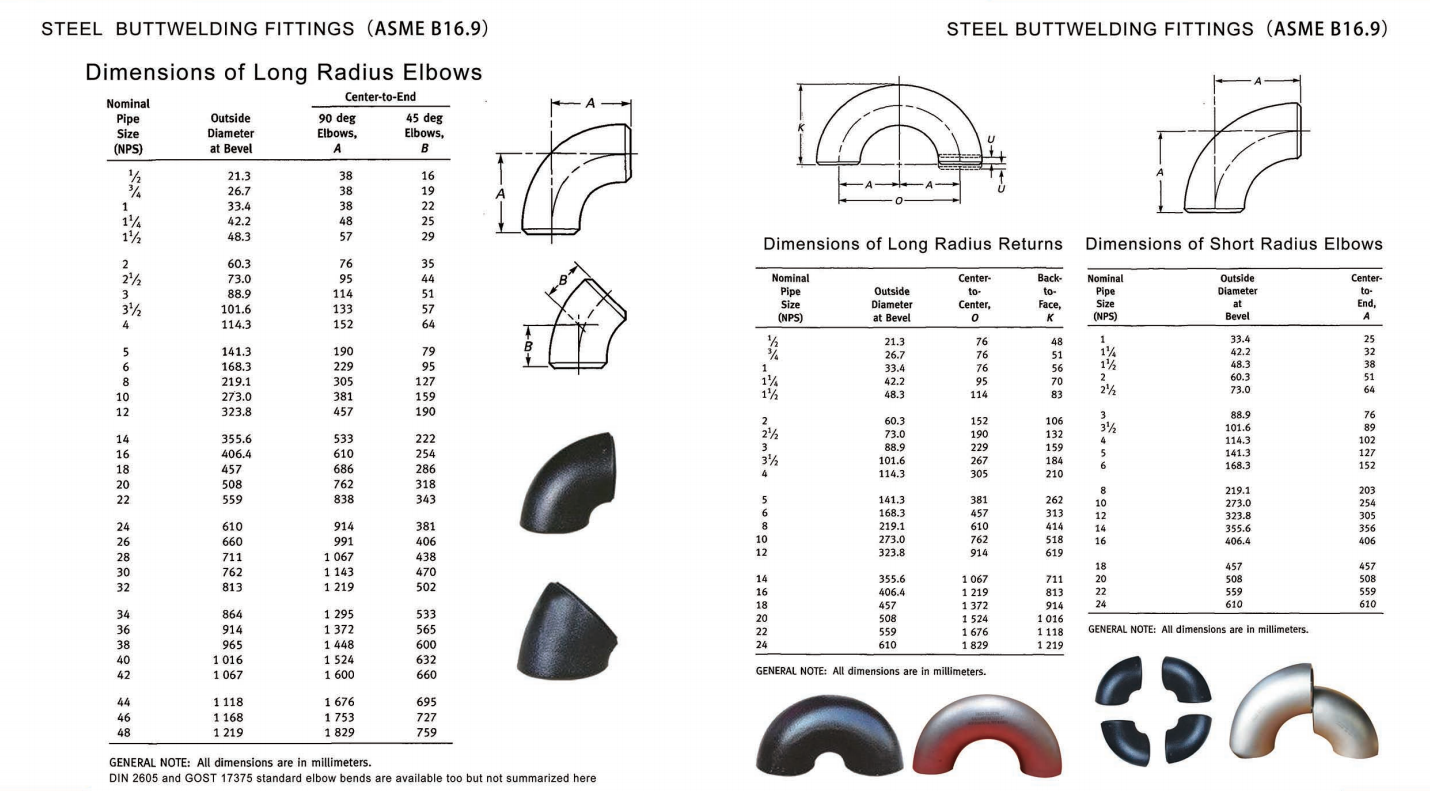

Data Reference

Product detail pictures:

Related Product Guide:

Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for Professional China Pipeline Compensation - Carbon Steel Seamless Bw Fittings Elbow 90 Deg – Xinqi , The product will supply to all over the world, such as: Bandung, Albania, Czech Republic, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top