Practical flat flange EN 1092-1

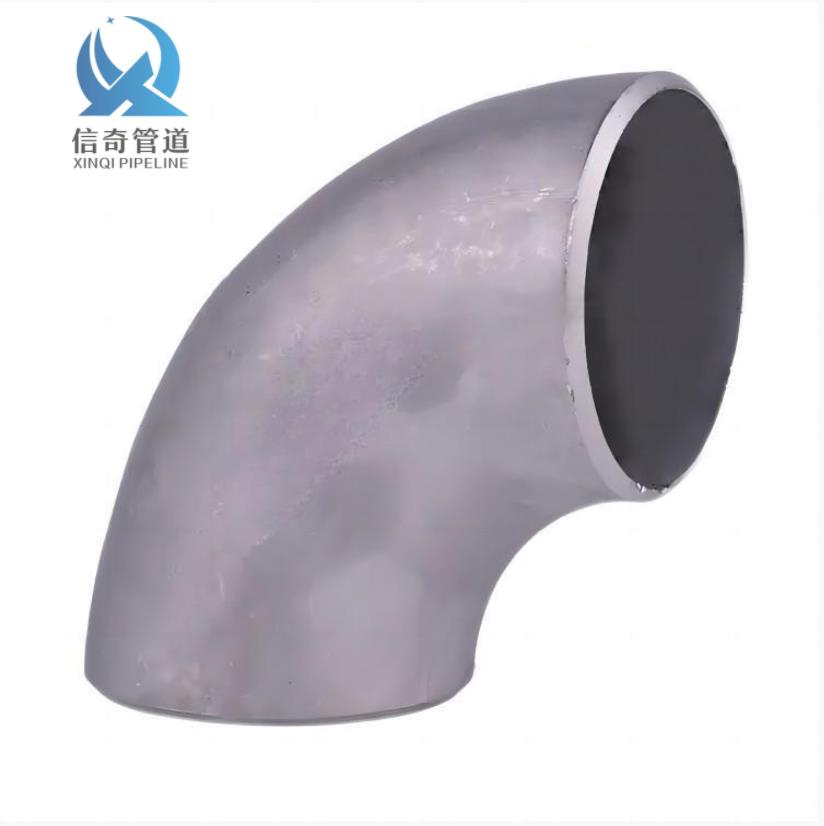

Picture Presentation

Product Data

| Slip On Plate Flange | |||||||||

| Material | Carbon steel | ASTM A105. ASTM A350 LF1. LF2, CL1/CL2, A234, S235JRG2, P245GH | |||||||

| Stainless steel | ASTM A182, F304/304L, F316/316L | ||||||||

| Standard | BS 4504 | PN2.5-PN40 DN10-DN2000 | |||||||

| Surface | Anti-rust oil, clear lacquer, Black lacquer, Yellow lacquer,hot-dipped Galvanized,electrical galvanized | ||||||||

| Connection | Welding, Threaded | ||||||||

| Technical | Forged, Casting | ||||||||

| Size | PN10-PN16, DN10-DN600 | ||||||||

| Package | 1. Wooden Case 2. As Customers' Requirements |

||||||||

| Applications | Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry,and general pipes connecting projects etc. | ||||||||

Product Introduction

Crafted using precision technology and expertise, our sliding plate flanges provide a simple and robust solution for joining pipes with fillet welds. Its freeform design distinguishes it from necked butt weld flanges, providing a simpler construction and requiring less material, making it a cost-effective choice for your piping needs.

We pride ourselves on offering a variety of high-quality products, including bellows, bellows compensators, power transmission couplings, elbows, tees, reducers, caps, and forged fittings. Our sliding plate flanges, in particular, are widely used in heating pipelines, oil, gas, chemical and thermal power plants, demonstrating their versatility and reliability in various industries.

Whether you require a reliable flange for your industrial, commercial or residential piping system, our practical flat face flange EN 1092-1 is the ideal choice. It complies with the EN 1092-1 standard, ensuring it meets the necessary requirements for quality and performance, giving you peace of mind and confidence in its functionality.

Processing steps

(1) Select the appropriate steel plate: when changing the tolerance size, please carefully consider the size of the selected steel plate

(2) Cutting and shearing: use steel plate cutting machine and polishing machine to cut steel plate to achieve dimensional accuracy and proportionality requirements.

(3) Steel plate welding: adopt linear arc welding, fasten the edge of the steel plate with a small clamp, and add a vertical weld at the weld.

(4) Assembly and adjustment: install and adjust various bolts to ensure the symmetry and direction of size and thread are consistent.

(5) Inspection: Vernier calipers are used to measure the flange thickness, outer diameter and weld width. Vernier calipers are used to measure the flange size.

(6) Polishing: polishing the edge voids to improve the appearance image.

Advantage

1. Slip-on plate flanges are a type of EN 1092-1 flat flange and are designed to be easy to install, making them a practical choice for a variety of piping systems.

2. Its simple construction and low material requirements make it a cost-effective choice for many industrial applications.

3. Slip-on plate flanges are connected to pipes with fillet welds, providing a safe, strong joint that can withstand high pressures and temperatures.

Shortcoming

1. One of the main problems is the possibility of leaks at joints, especially under extreme operating conditions.

2. Additionally, fillet weld connections, while convenient, may not provide the same level of structural integrity as fully welded flanges.

Our Services

1. One of our main products is the slip-on plate flange, which provides a versatile and efficient method of joining pipes with fillet welds. This type of flange is known for its simple construction and minimal material requirements, making it a cost-effective choice for a variety of applications.

2. In addition to our products, our team is committed to providing excellent customer service and technical support. We understand the importance of finding the right solution for your unique needs, and we're committed to guiding you through the selection process and addressing any questions or concerns you may have.

FAQ

Q1. What is EN 1092-1?

EN 1092-1 is a European flange standard designed to ensure interchangeability and compatibility between different components in piping systems. It specifies the dimensions, tolerances and technical requirements for flat face flanges, making it an important guide for manufacturers and users.

Q2. What are the main features of flat flange EN 1092-1?

Flat flanges EN 1092-1 are renowned for their precision engineering, high-quality materials and reliable performance. It is designed to withstand varying pressure, temperature and environmental conditions, making it suitable for a wide range of applications.

Q3. How do I choose the appropriate flat face flange EN 1092-1 for my application?

When selecting an EN 1092-1 flat face flange, factors such as pipe size, pressure rating, material compatibility and environmental conditions must be considered. Our team of experts can provide personalized guidance to help you choose the flange that best suits your specific needs.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top