OEM/ODM China Long Radius Elbow - Stainless Steel 304 Seamless Pipe Cap–ASME B16.9 – Xinqi

OEM/ODM China Long Radius Elbow - Stainless Steel 304 Seamless Pipe Cap–ASME B16.9 – Xinqi Detail:

Product Description

Pipe fittings welded on the pipe end or installed on the external thread of the pipe end to cover the pipe

Stainless steel pipe cap is also called plug or head. The pipe cap includes the design of convex pipe cap, conical shell, reducing section, flat cap and tight mouth.

Basic Data

Stainless steel material: 304 304L 316 316L 321 2520 310, 317, etc

Diameter: DN15-DN1200

Wall thickness: SCH5-SCH160

Standard: ASME DIN JIS BS GB/T JB SH HG

Applications: water, beverage, beer, food, petrochemical, nuclear power, machinery, medical equipment, fertilizer, shipbuilding, waterproof treatment, pipes, etc., pipe fittings welded on the pipe end or installed on the external thread of the pipe end to cover the pipe. It is used to close the pipeline and has the same function as the plug.

Packaging: wooden case, carton

Service: provide technical consultation, installation guidance, etc

Classification

By connection:

1. Common pipe cap

2. Threaded pipe cap

3. Ferrule cap

4. Clamp cap

5. Socket cap

6. Adhesive pipe cap

7. Hot melt pipe cap

8. Rubber ring connecting pipe cap

By material:

1. Cast steel pipe cap

2. Cast iron pipe cap

3. Stainless steel pipe cap

4. Plastic pipe cap

5. PVC pipe cap

6. Rubber pipe cap

7. Graphite pipe cap

8. Forged steel pipe cap

9. PPR pipe cap

10. Alloy pipe cap

11. PE pipe cap

12. ABS pipe cap

During splicing, only radial and circumferential weld directions are allowed. This requirement may be cancelled in the future for large pipe caps. The splicing distance shall be more than 3 δ, It shall not be less than 100mm (the welding heat affected zone is a high stress zone, and the chemical composition in this zone will be burned. Therefore, it is necessary to avoid the high stress zone, which is related to the thickness. According to practical experience, the stress attenuation length is greater than 3 δ,And not less than 100mm). However, refrigeration equipment is difficult to meet this requirement, which has its particularity.

100% radiographic or ultrasonic testing shall be carried out on the splicing weld of the formed head after splicing, and the qualification level shall follow the equipment shell. The inspection level and proportion of the final formed weld are the same as that of the equipment shell, which is high waste.

For example, if the equipment shell is 20% tested, III is qualified. The butt weld and final weld of the bulkhead are also qualified as III, and the welding joint coefficient is 0.85;

If the equipment shell is 100% tested, II is qualified. The butt weld and the final weld of the bulkhead are also II qualified, and the welding joint coefficient is 1

Therefore, although the bulkhead splicing is 100% tested, the qualification level is different, which follows the equipment shell.

But pay attention to the process and manufacturing process:

The correct method is: blanking (scribing) – small plates assembled into large plates – forming – NDT

If the inspection is not conducted before forming, it is wrong to ensure that it is still qualified after forming. That is to say, NDT refers to the final NDT.

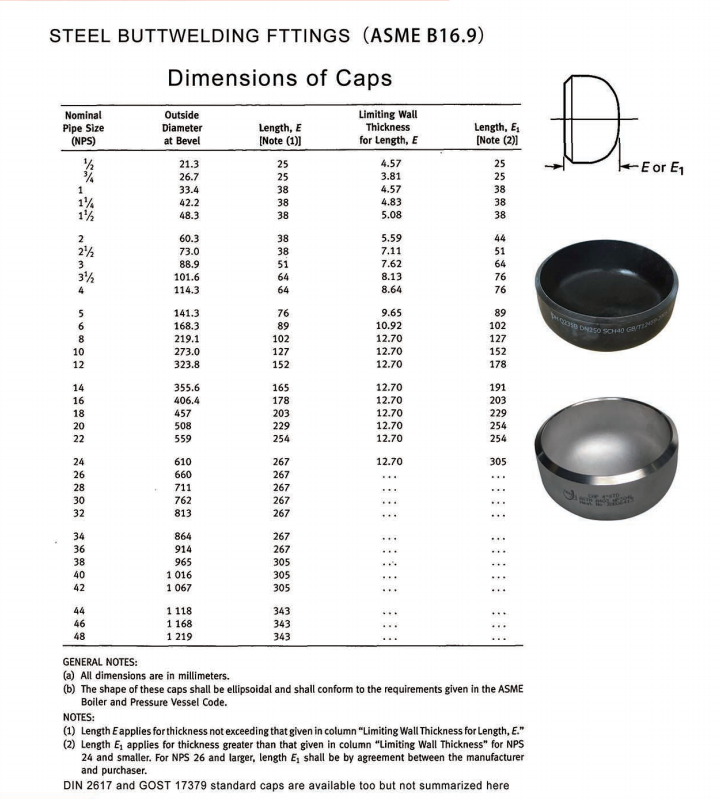

Data Reference

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for OEM/ODM China Long Radius Elbow - Stainless Steel 304 Seamless Pipe Cap–ASME B16.9 – Xinqi , The product will supply to all over the world, such as: Istanbul, South Africa, New York, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top