OEM China Api Q1 Flange - ASME/ANSI B16.5 Stainless/Carbon Steel Socket Weld Flange – Xinqi

OEM China Api Q1 Flange - ASME/ANSI B16.5 Stainless/Carbon Steel Socket Weld Flange – Xinqi Detail:

Socket Weld Flange Discription

Socket welding flange refers to the flange in which the end of the pipe is inserted into the flange ring step and welded on the pipe end and the outside. There are two types with and without neck. The flange with neck pipe has good rigidity, small welding deformation and good sealing performance, and can be used in the occasions where the pressure is 1.0~10.0MPa. Type B flanges for containers are also socket welding flanges, which are used in occasions with high sealing requirements. When designing, the socket welding flange can be checked according to the integral flange.

Features

Advantages and Disadvantages

Socket welding is usually used for small pipes smaller than DN40 in diameter and is more economical. Socket welding is the process of first inserting a socket and then welding (for example, there is a type of flange called a socket flange, which is a projection weld flange, which is a connection when connecting to other parts, such as valves. Socket welding Usually the pipe is inserted into the flange and welded. Socket welding can be used for magnetic particle or penetration testing (carbon powder, penetrating carbon steel such as stainless steel) and is recommended if the fluid in the pipe does not require high welding requirements Socket welding, the type of connection that is easy to detect is mainly small-diameter valves and pipes, which are used for pipe joints and pipe welding. Small-diameter pipes usually have thin walls, which are prone to edge dislocation and ablation, and are difficult to butt welding, suitable for socket welding. Socket weld and socket.

Welded sockets are often used under high pressure due to their reinforcing effect, but socket welding also has disadvantages. One is that the stress state after welding is not good, and it is difficult to completely melt. Trends are: piping systems with gaps and therefore unsuitable for crevice corrosion-sensitive media and piping systems with high cleanliness requirements; the use of socket welds; and ultra-high pressure piping. Large wall thicknesses are available even in small diameter pipes, and socket welds can be avoided as much as possible by butt welding.

Products Display

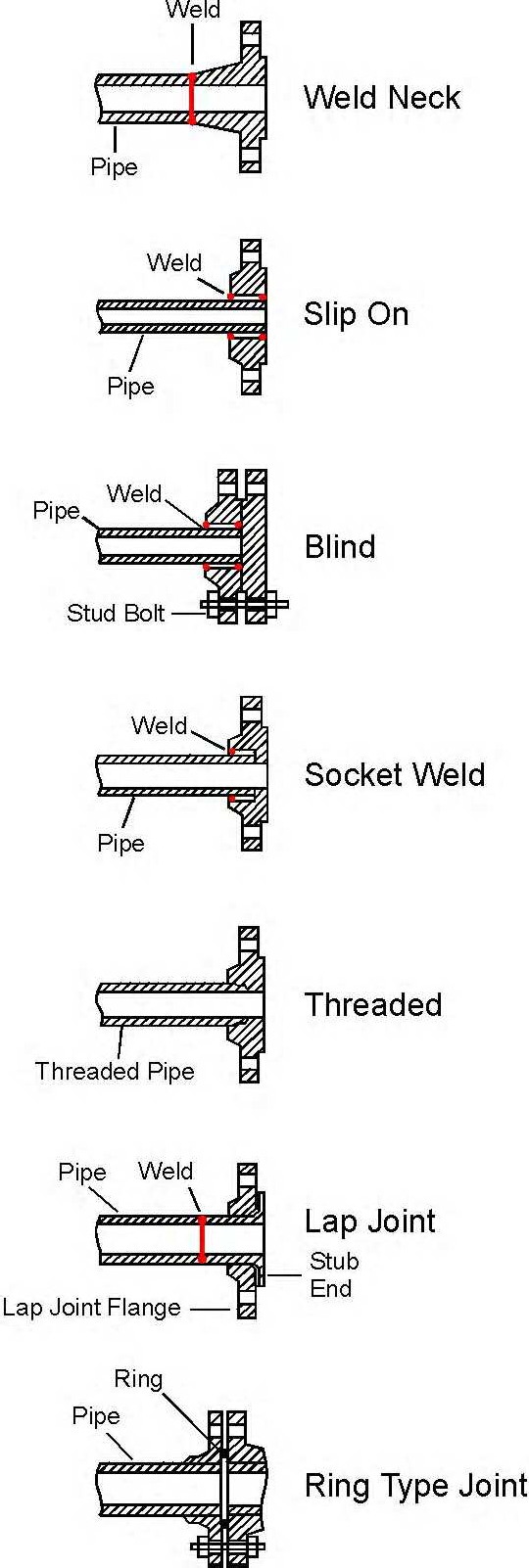

Flange Types

Weld Neck

This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications

erosion inside the pipeline. The weld neck is therefore favoured in critical applications.

Slip-on

This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications.

Blind

This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange.

Socket Weld

This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics.

Threaded

This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required.

Lap Joint

These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel.

Ring Type Joint

This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

Production Machines and Packaging

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for OEM China Api Q1 Flange - ASME/ANSI B16.5 Stainless/Carbon Steel Socket Weld Flange – Xinqi , The product will supply to all over the world, such as: Egypt, Qatar, El Salvador, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top