Nozzle Type Sleeve Compensator with Flange signle Way

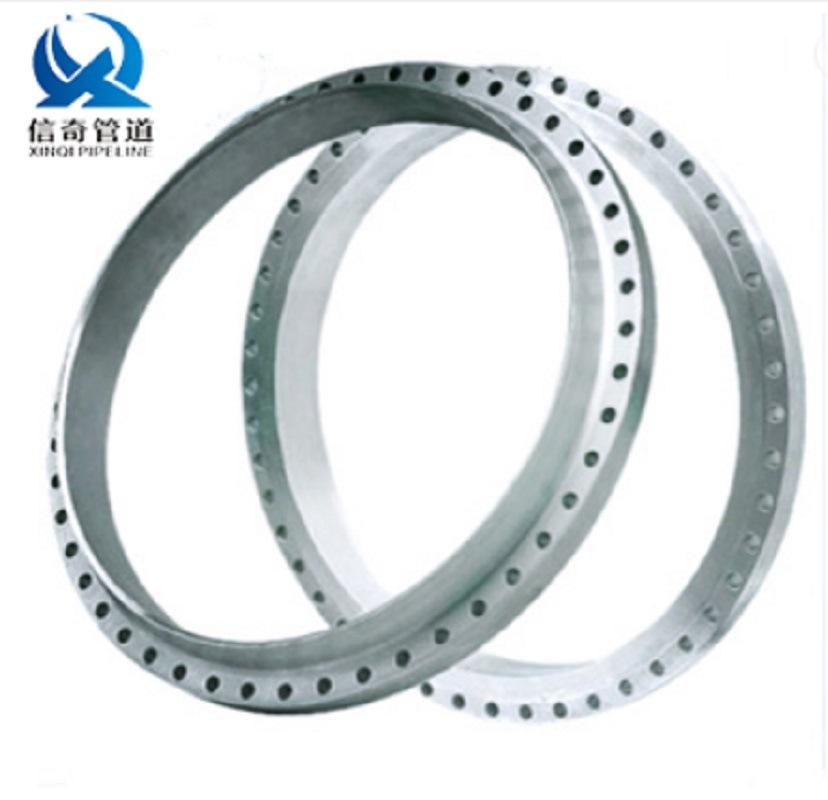

Picture Presentation

Product Description

The sleeve compensator, called tubular expansion joint, is a compensation device for thermal fluid pipelines. It is mainly used for the absorption and compensation of axial thermal expansion displacement after the auxiliary installation of linear pipelines. It is a compensator directly installed in any pipeline conveying non corrosive unidirectional or multi-directional fluids. Sleeve type compensator It is widely used in the transmission pipeline of urban heating, metallurgy, mining, power generation, petrochemical, construction and other industries. It is mainly composed of sleeve (core tube), shell, sealing material, etc.

The sleeve compensator, called tubular expansion joint, is a compensation device for thermal fluid pipelines. It is mainly used for the absorption and compensation of axial thermal expansion displacement after the auxiliary installation of linear pipelines. It is a compensator directly installed in any pipeline conveying non corrosive unidirectional or multi-directional fluids. Sleeve type compensator It is widely used in the transmission pipeline of urban heating, metallurgy, mining, power generation, petrochemical, construction and other industries. It is mainly composed of sleeve (core tube), shell, sealing material, etc.

Structural Characteristics

It is mainly composed of sleeve (core tube), shell, sealing material, etc. It is used to compensate the axial expansion of the pipe and axial rotation at any angle With small volume and large compensation, it is suitable for hot water, steam, grease and other media. The sliding sleeve can compensate for thermal expansion by sliding the outer sleeve.

The inner sleeve of the sleeve type compensator is connected with the pipeline. It adopts the principle and structure of high-performance self pressure dynamic seal. It can slide freely in the shell with the expansion and contraction of the pipeline, and can meet the sealing requirements of any pipeline The shell and inner sleeve are sealed with a new type of synthetic material, which can withstand high temperature, corrosion and aging. The applicable temperature is - 40 to 150, and can reach 350 under special circumstances. It can not only ensure axial sliding, but also ensure that the medium in the pipe does not leak

The sleeve type compensator is designed with an anti pulling device, which can ensure that it will not be pulled out when it expands to the limit position, thus greatly improving the safety of the whole pipe network.

Sleeve type compensator is applicable to medium engineering pressure ≤ 2.5MPa and medium temperature - 40 ºC~600 ºC.

The sleeve type compensator adopts a new sealing material, flexible graphite ring, which has the characteristics of high strength, small friction coefficient (0.04~0.10), no aging, good effect, convenient maintenance, etc.

Data Reference

| DN | D | D2 | D3 | (mm) | △L max | L max | Pc(N)= 1.6MPa |

(kg) |

| 15 | 14 | 18 | 95 | 36 | 150 | 640 | 4.69 | |

| 20 | 18 | 23 | 105 | 36 | 150 | 640 | 5.62 | |

| 25 | 24 | 30 | 115 | 36 | 150 | 640 | 1069 | 7.38 |

| 32 | 30 | 36 | 120 | 36 | 150 | 640 | 1311 | 8.38 |

| 36 | 36 | 43 | 125 | 36 | 200 | 740 | 1415 | 10.45 |

| 40 | 41 | 48 | 130 | 36 | 200 | 740 | 1518 | 11.62 |

| 50 | 47 | 55 | 160 | 56 | 200 | 760 | 1932 | 16.42 |

| 80 | 78 | 87 | 195 | 56 | 200 | 760 | 3002 | 26.92 |

| 100 | 94 | 106 | 215 | 56 | 250 | 895 | 6271 | 41.8 |

| 125 | 117 | 131 | 245 | 56 | 250 | 895 | 7750 | 52.02 |

| 150 | 143 | 157 | 280 | 56 | 250 | 895 | 9288 | 69.16 |

| 175 | 176 | 192 | 335 | 70 | 250 | 920 | 13251 | 94.74 |

| 200 | 201 | 217 | 335 | 70 | 300 | 1020 | 14977 | 106.28 |

| 250 | 253 | 270 | 390 | 70 | 350 | 1135 | 21297 | 142.74 |

| 300 | 303 | 322 | 440 | 91 | 350 | 1155 | 25399 | 175.44 |

| 350 | 353 | 373 | 500 | 91 | 400 | 1360 | 29421 | 262.66 |

| 400 | 404 | 426 | 565 | 91 | 400 | 1360 | 33286 | 288.05 |

| 450 | 455 | 478 | 615 | 91 | 400 | 1360 | 33852 | 313.43 |

| 500 | 505 | 528 | 670 | 91 | 450 | 1460 | 36234 | 377.82 |

| 600 | 603 | 630 | 780 | 91 | 450 | 1480 | 43205 | 531.64 |

| 700 | 693 | 720 | 880 | 91 | 450 | 1525 | 61771 | 629.71 |

| 800 | 792 | 820 | 995 | 112 | 500 | 1655 | 70398 | 880.22 |

| 900 | 890 | 920 | 1095 | 112 | 500 | 1655 | 79025 | 986.36 |

| 1000 | 990 | 1020 | 1195 | 122 | 500 | 1655 | 87653 | 1087.72 |

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top