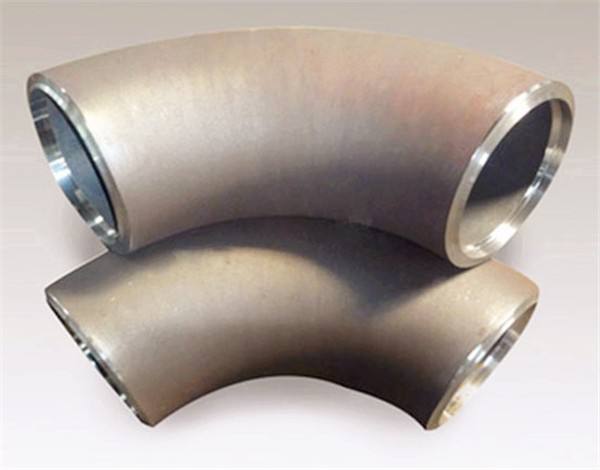

Welded elbow is made of pipe bending and can be welded, so it is called welded elbow, which does not mean that it has welds. In fact, on the contrary, welded elbow is made of straight pipe stamping and bending. Considering the structural stress, seamless pipe is generally used. Instead of welded pipe., The so-called seamless elbow is a casting and cannot be welded.

Welded elbow is not the same as seamless elbow, but it also has overlap. The production of elbow is divided into welding, stamping, pushing and casting. Seamless refers to the elbow without welding seam, not welded elbow. Stamped elbow has straight seam stamping elbow and seamless stamping elbow, which is determined by the nature of pipe embryo.

The elbow is a seamless product and can be processed directly from the seamless pipe; Elbows are joints, which are created by welding.

The difference between welded elbow and seamless elbow is that butt welded elbow has two welds, straight welded elbow has one weld, and seamless elbow has no weld.

1. Appearance difference The difference between seamless elbow and welded elbow is whether there is weld. In addition, the thickness of seamless elbow is uneven compared with that of welded elbow.

2. Differences in molding process The process of using seamless elbow is the same as that of welding elbow. However, the difference between the two is that elbow manufacturing is divided into welding, stamping, pushing and casting. Seamless elbow is made of seamless steel pipe, without welding seam or welded elbow. The welded elbow is made of steel plate made by bending and different welding processes.

3. Different uses Seamless elbows are mainly used as pipes or structural parts for conveying fluids in the machinery industry, while joint welded elbows are mainly used in the construction industry, such as low-pressure fluids, such as water and compressed air. However, the penstocks involved are seamless.

4. Available size difference For most manufacturers of seamless pipe elbows in China, the size of seamless pipe elbows is 24 inches and the outer diameter is 609.6 mm. In contrast, there is no limit to welded bends, which can range from 1-1/2 inch 48.3mm to 100 inch 2540mm.

5. Different prices As the seamless production process is more complex, the price is more expensive than the joint elbow, and the joint is mainly made of steel plate (steel strip) by secondary welding, which is cheap and widely used.

Post time: Nov-22-2022