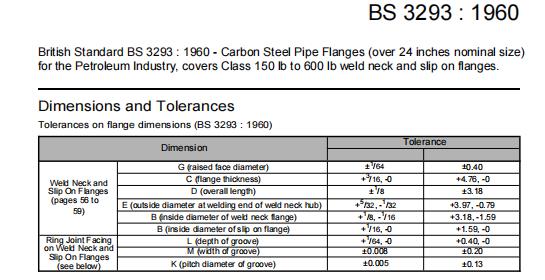

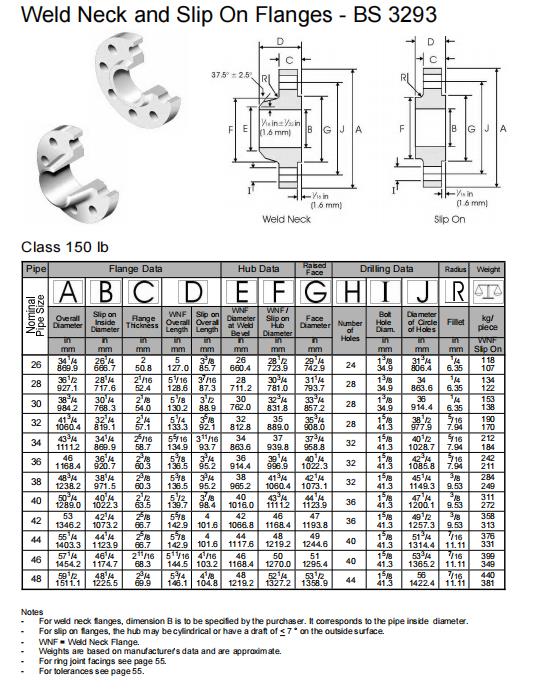

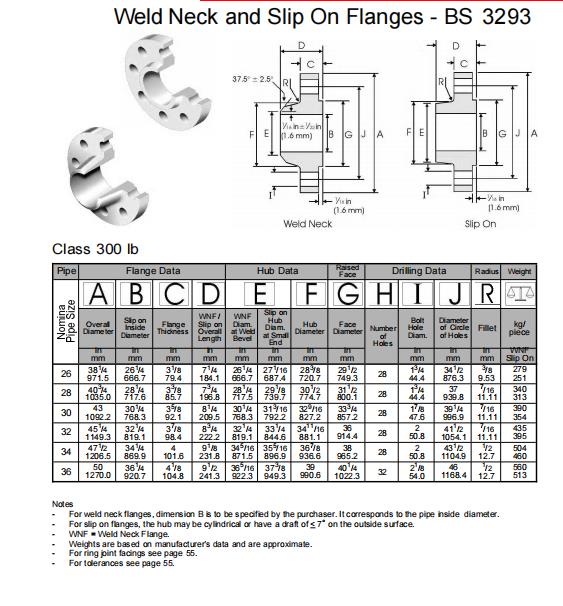

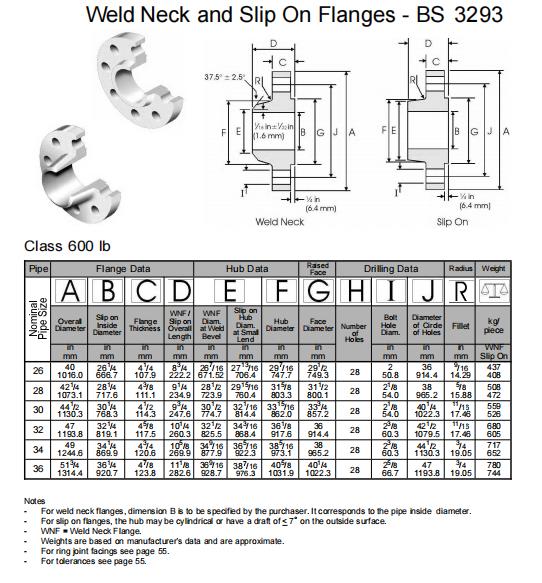

British Standard BS 3293: 1960-Carbon Steel Pipe Flanges(over 24 inches nominal size) for Petroleum Industry, covers Class 150lb to 600lb weld neck flanges and slip on flanges.

The following will introduce the dimensions and tolerances of the welding neck flange and the neck flat welding flange in BS 3293.

BS3293 weld neck and slip on flange belongs to the American standard flange standard system. It is a manifestation of American standard flange (also known as ANSI method) and one of the commonly used flanges on equipment or pipeline.

BS 3293:1960 is a material and size. This standard is only applicable to forged carbon steel Slip-on flange and welded neck flange of nominal diameter 26 inches and larger for petroleum Industrial drilling, bolting, finishing and thickness

Dimensions also apply to integral ends.

Flanges for valves and fittings. Four types of flanges are provided, namely class150, 300, 400 and 600. BS 3293:1960 does not include: pressure/temperature ratings; The name of the flange reference is used for identification purposes

Cross reference only: BS 1503, BS 1560, BS 1750, BS 3351, ANSI B16.20, ASTM A 105

Difference between Weld Neck Flanges and Slip On Flanges

1. Different weld forms:

Radiographic inspection can be conducted for the welds of the neck butt welding flange, but not for the neck flat welding flange. The welding form of neck butt-welding flange and pipe is circumferential weld, while the welding form of flat welding flange and pipe is fillet weld. Butt welding is a butt circumferential weld, and flat welding is two fillet circumferential welds. The difference between the two is that the weld connecting the neck butt-welding flange and the nozzle belongs to Class B seam, while the weld connecting the neck butt-welding flange and the nozzle belongs to Class C seam.

2. Different materials:

The material of the neck butt welding flange is usually made of forged steel parts by machining. The material of the slip-on welding flange with neck is made of ordinary steel plate with required thickness through machining.

3. Different nominal pressures:

The nominal pressure of the neck butt-welding flange is 1-25MPa, which is higher. The nominal pressure of the neck flat welding flange is 0.6-4MPa. Compared with the neck flat welding flange, its pressure level is lower and its ability to adapt to pressure is also lower

Post time: Feb-23-2023