High pressure flange is used to connect pipes or equipment with pressure higher than 10MPa. At present, it mainly includes traditional high-pressure flange and high-pressure self tightening flange.

Traditional High Pressure Flange

Overview of Traditional High Pressure Flange

The traditional high-pressure flange is a part that uses the plastic deformation of the sealing gasket (oval gasket, octagonal gasket, lens gasket, etc.) to achieve the sealing effect. It is connected to the pipe end to make the pipe and pipe connect with each other. There are holes on the flange, and the two flanges are tightly connected by the stud bolts.

Traditional high-pressure flange is generally composed of a pair of flanges, a gasket and several bolts and nuts. The sealing gasket is installed between the sealing surfaces of two flanges. After tightening the nut, the specific pressure on the sealing gasket surface reaches a certain value, which will cause plastic deformation and make the connection tight. This form can be used for flammable, explosive, toxic media and high pressure occasions, but the sealing reliability is poor.

(High pressure flange connection diagram-Welding Neck Flange)

Others: Slip On Flange、Slip On Plate Flange

Features of Traditional High-Pressure Flange

1. The sealing principle belongs to plastic deformation

2. Bolted connection

3. Bolts shall bear tension, temperature difference stress, bending moment, torque and other external stresses

4. It is bulky and heavy, and it is difficult to install and position.

5. Unstable sealing performance, especially in harsh conditions (high temperature, high pressure, and highly toxic medium), is prone to leakage, causing serious consequences.

Application characteristics of Traditional High-Pressure Flange:

High pressure flange is mainly used in pipeline installation. High pressure flange connection is an important connection method for pipeline construction. It mainly connects the connection between pipes, playing an important role and value. High pressure flange connection is to fix two pipes, pipe fittings or equipment on a flange plate respectively, add flange gaskets between the two flanges, and fasten them together with bolts to complete the connection. Some pipe fittings and equipment have their own flanges, which also belong to flange connection.

Performance of Traditional High-Pressure Flange:

1. Wear resistance: the content of Al2O3 in the ceramic layer of the ceramic lined composite steel pipe is greater than 95%, and the micro hardness is HV1000-1500, so it has extremely high wear resistance. Its wear resistance is more than ten times higher than that of the quenched medium carbon steel, and better than that of tungsten carbide.

2. Corrosion resistant ceramics are neutral materials with stable chemical properties, excellent corrosion resistance and acid resistance, and can resist various inorganic acids, organic acids, organic solvents, etc. Its corrosion resistance is more than ten times that of stainless steel.

High pressure Self Tightening Type

Product introduction of High Pressure Self Tightening Type:

High pressure self tightening flange is a new type of high pressure flange, which is more conducive to pipeline connection under severe working conditions such as high pressure, high temperature and high corrosion. The traditional flange relies on the plastic deformation of the gasket to achieve the sealing function, which belongs to the soft seal. The core of the high-pressure self tightening flange is a unique new seal, which is a hard seal formed by the elastic deformation of the sealing lip (T-arm) of the sealing ring.

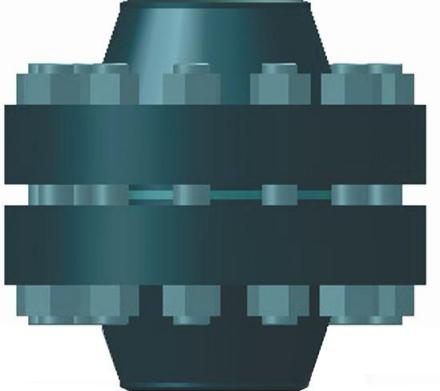

Profuct Structure of High Pressure Self Tightening Type:

Generally composed of ferrule, socket, sealing ring and bolt.

1. Metal sealing ring: the sealing ring is the core part of high-pressure self tightening flange, and its cross section is similar to “T” shape. After the flange is assembled, the rebar of the seal ring is clamped by the end faces of two sets of HUB joints and forms a whole with the header, which greatly improves the strength of the connection part; The two arms of the “T” section, namely the sealing lip, and the inner cone of the sleeve joint form a sealing area, which extends freely under the external force (within the yield limit) to form a seal.

2. Socket: after the two socket HUBs are clamped by the ferrule, they are pressed on the rib of the seal ring, and the sealing lip deviates from the internal sealing surface of the socket, which elastically returns the load of the internal sealing surface of the socket back to the lip of the seal ring, forming a self reinforced elastic seal.

3. Ferrule: the ferrule can be freely adjusted in 360 ° direction for easy installation.

4. Four sets of spherical bolts: generally, only four sets of tangential high-pressure spherical bolts are required for each set of high-pressure self tightening flange to complete the overall firmness

Product Features of High Pressure Self Tightening Type:

1. Sealing method: the core of high-pressure self tightening flange is a unique metal to metal new seal, that is, the seal is formed by the elastic deformation of the sealing lip (T-arm) of the sealing ring, which belongs to hard seal; The combination of sleeve, ferrule and sealing ring is used to form a strong rigid body, which makes the strength of the connection part far greater than the strength of the pipe base metal itself. When pressed, the rib and lip play the role of strength and sealing respectively, which can not only self tighten the seal, but also strengthen the pipeline, greatly enhancing the overall strength of the connection part

2. Tensile property: In most cases, the high-pressure self tightening flange in the connection can bear the tensile load better than the pipe itself; Destructive tests showed that the flange was still intact without leakage after the pipeline failed under tensile load.

3. Bending resistance: a large number of tests show that the flange will not leak or become loose when bearing large bending load. Actual test: DN15 high pressure self tightening flange is welded on the pipe and subjected to several cold bends. The connection of high pressure self tightening flange will not leak and the bolts will not become loose.

4. Compressibility: in normal pipeline applications, high-pressure self tightening flanges will not bear overload compression; When a higher compression load occurs, the maximum load on the high-pressure self tightening flange is determined by the ultimate strength of the pipe.

5. Impact resistance: small and compact geometric size, which can withstand the impact force that traditional high-pressure flange cannot bear; The unique metal to metal sealing structure greatly enhances its impact resistance.

Corrosion resistance: the corrosion resistance of different materials can meet the special corrosion protection requirements of different use environments.

Post time: Dec-06-2022