News

-

What are the similarities and differences between weld neck flange and long welding neck flange?

Weld neck flanges and long welding neck flanges are two common types of flange connections that are similar in some respects but also have some notable differences. Here are their similarities and differences: Similarities: 1. Connection purpose: Both the weld neck flange and the long neck we...Read more -

What material is ASTM A516 Gr.70 made of?

ASTM A516 Gr.70 is a carbon steel material. Carbon steel is a class of steel materials containing carbon as the main alloying element, usually has good weldability and is therefore often suitable for welded manufacturing. ASTM A516 Gr.70 has a moderate carbon content which makes it perform well i...Read more -

Stainless Steel DIN-1.4301/1.4307

1.4301 and 1.4307 in the German standard correspond to AISI 304 and AISI 304L stainless steel in the international standard respectively. These two stainless steels are commonly referred to as “X5CrNi18-10″ and “X2CrNi18-9″ in German standards. 1.4301 and 1.4307 stainless ...Read more -

Classification of steel pipes

Steel pipe is a type of metal pipe, usually made of steel, used to transport liquids, gases, solids and other substances, as well as for structural support and other engineering applications. Steel pipes have a variety of types, specifications and uses, the following are some common steel pipe t...Read more -

Differences and similarities between aluminum and carbon steel flanges and stainless steel flanges.

Aluminum flanges, carbon steel flanges and stainless steel flanges are commonly used connecting elements in the industrial field for connecting pipes, valves, pumps and other equipment. They have some similarities and differences in materials, performance and usage. Similarities: 1. Connection fu...Read more -

Where are aluminum flanges generally used?

Aluminum flange is a component that connects pipes, valves, equipment, etc., and is usually used in industry, construction, chemical industry, water treatment, oil, natural gas and other fields. Commonly used standards are also 6061 6060 6063 Aluminum flanges have the characteristics of light wei...Read more -

Introduction to Russian Standard GOST 19281 09G2S

The Russian standard GOST-33259 09G2S is a low alloy structural steel commonly used for manufacturing various components of engineering and building structures. It meets the requirements of the Russian national standard GOST 19281-89. 09G2S steel has high strength and toughness, suitable for appl...Read more -

VIETNAM-VIETBUILD 2023 International Exhibition

“VIETBUILD 2023 is the leading International Exhibition on Construction – Building Materials – Real Estate & Interior – Exterior Decoration, directed and sponsored by Vietnam Ministry of Construction, taking place at Vietnam Sky Expo Exhibition & Convention Center ...Read more -

AWWA C207 – Blind flange、Threaded flange、Welding neck flange、Slip on flange

AWWA C207 actually refers to the C207 standard developed by the American Water Works Association (AWWA). It is a standard specification for pipe flanges for water supply, drainage, and other liquid transport systems. Flange type: The AWWA C207 standard covers different types of flanges, including...Read more -

ANSI B16.5 – Pipe Flanges and Flanged Fittings

ANSI B16.5 is an international standard issued by the American National Standards Institute (ANSI), which regulates the dimensions, materials, connection methods and performance requirements of pipes, valves, flanges and fittings. This standard specifies the standard dimensions of steel pipe flan...Read more -

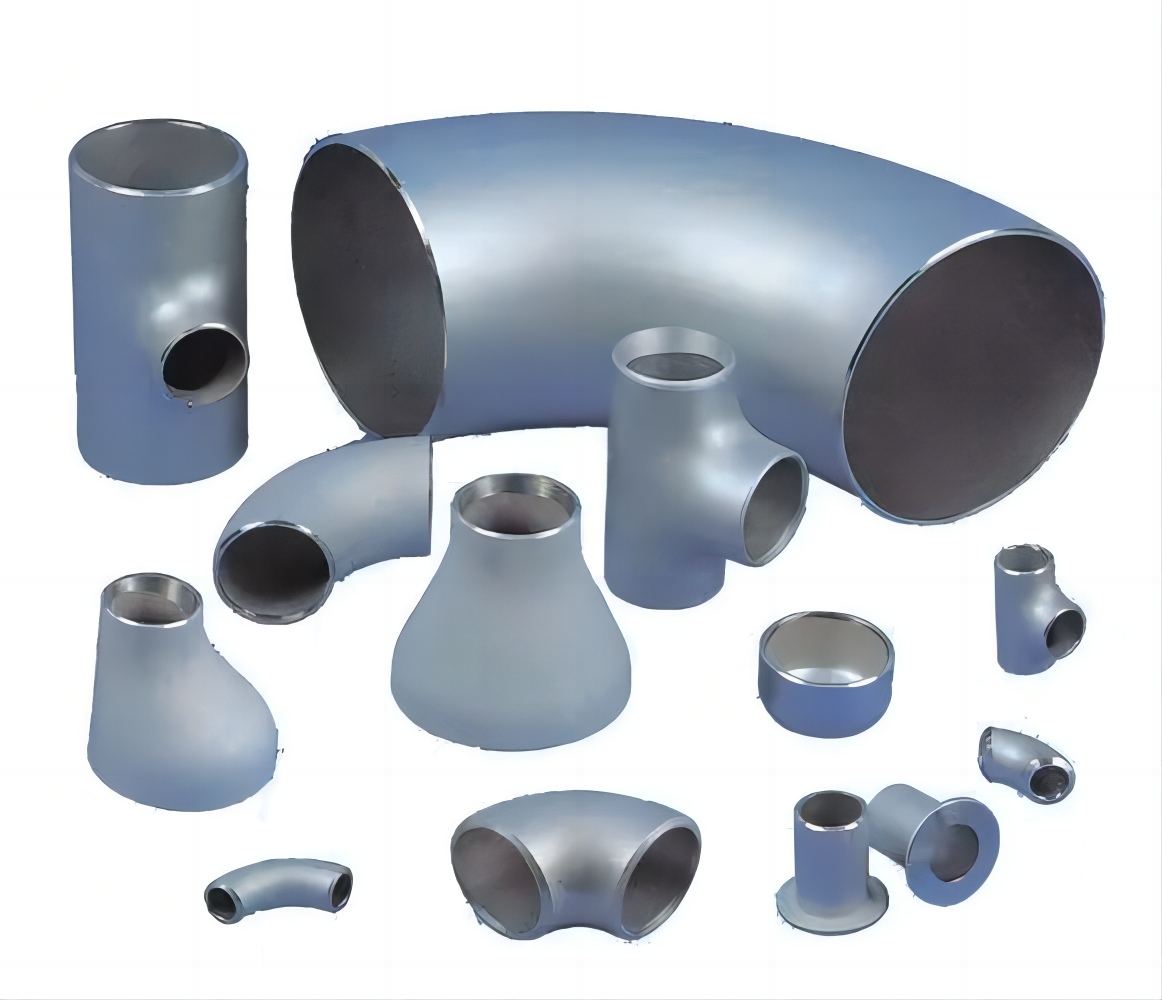

ASME B16.9: International Standard for Forged Butt Welding Fittings

The ASME B16.9 standard is a standard issued by the American Society of Mechanical Engineers (ASME) entitled “Factory-Made Wrought Steel Butt-welding Fittings“. This standard specifies requirements for dimensions, manufacturing methods, materials, and inspections of steel welded and s...Read more -

Introduction to Electroplated Yellow Paint

Electroplated yellow paint is a type of coating that undergoes surface treatment after electroplating, also known as post electroplating coating or post electroplating coating. It is a process of electroplating on metal surfaces followed by special coating treatment to achieve aesthetic, anti-cor...Read more -

Aluminium alloy – for use in flanges and fittings

When it comes to the materials of flanges and pipe fittings, we often mention stainless steel and carbon steel. Is it just these two? Is there anything else? In fact, there are many other materials besides this, but they are not chosen by us due to various reasons and environmental influences. An...Read more -

Coupling

Coupling is an important component in mechanical transmission in industrial pipeline connections. Torque is transmitted through the mutual connection between the driving shaft and the driven shaft. It is a pipe fitting with internal threads or sockets used to connect two pipe segments. A pipe c...Read more -

Do you know anything about bushing as a pipe fitting component?

Bushing, also known as hexagonal internal and external threaded joints, is generally made by cutting and forging hexagonal rods. It can connect internal and external threaded fittings of two pipes with different diameters and plays an irreplaceable role in pipeline connection. Specifications: Th...Read more -

Classification, characteristics and uses of rubber expansion joints

Rubber expansion joint is a kind of elastic element used to compensate the deformation and stress caused by Thermal expansion, vibration and vibration in pipes, vessels and other systems. According to different rubber materials, rubber expansion joints can be divided into two types: natural rubbe...Read more -

Do you know what the plating in flanges is?

Electroplating is a process that utilizes electrochemical principles to cover metal or other materials on the surface of an object. Through the coordination of electrolyte, anode, and cathode, metal ions are reduced to metal on the cathode through current and attached to the surface of the plated...Read more -

Flanges and pipe fittings using electroplating spray yellow paint process

In addition to conventional electroplating processes, we often see a combination of electroplating and yellow paint spraying on flanges. It is in the form of electroplated yellow paint. Electroplating and spraying yellow paint is a surface treatment process that combines electroplating and sprayi...Read more -

About Lap Joint

Loose flange is also known as lap joint flange. It is a type of steel component that is often used as a modification of the connecting material. Loose flange is the use of flanges, steel rings, etc. to cover the flange on the pipe end, and the flange can move on the pipe end. The steel ring or fl...Read more -

WELDOLET-MSS SP 97

Weldolet, also known as butt welded branch pipe stand, is a type of branch pipe stand that has been widely used in recent years. It is a reinforced pipe fitting used for branch pipe connections, which can replace traditional branch pipe connection types such as reducing tees, reinforcing plates, ...Read more -

How should the butt welded flange be properly installed?

The use range of butt welded flanges is relatively broad, and the requirements for installation will also be relatively high. The following also introduces the installation sequence and precautions for butt welded flanges The first step is to organize the inner and outer sides of the connected st...Read more -

Application field and characteristics of flexible rubber expansion joint

Flexible rubber expansion joint is also called flexible winding rubber joint, rubber compensator, rubber elastic joint. The device at the inlet and outlet of the pump can effectively prevent the transmission of vibration and sound when the pump is working, play the effect of shock absorption and ...Read more -

Comparison between single sphere rubber joint and double sphere rubber joint

In daily use, the role played by single ball rubber soft joints and double ball rubber joints between metal pipelines is easily overlooked, but they are also crucial. Single ball rubber joint is a hollow rubber product used for portable connection between metal pipelines. It consists of inner and...Read more -

What are the common malfunctions and problems with flanges?

Flange is a common pipeline connection method with a high frequency of use, but it is inevitable that some faults will occur during use. Below, we will introduce common faults and solutions of flanges. 1. Flange leakage Flange leakage is one of the most common faults in flange connections. The re...Read more -

Stub Ends For Flange Connection

What is a stub end? How should it be used? Under what circumstances do you use it? People often have such questions, let’s discuss them together. The stub end is often used together with the lap joint flange to form a substitute for the welding neck flange connection, but remember that it c...Read more -

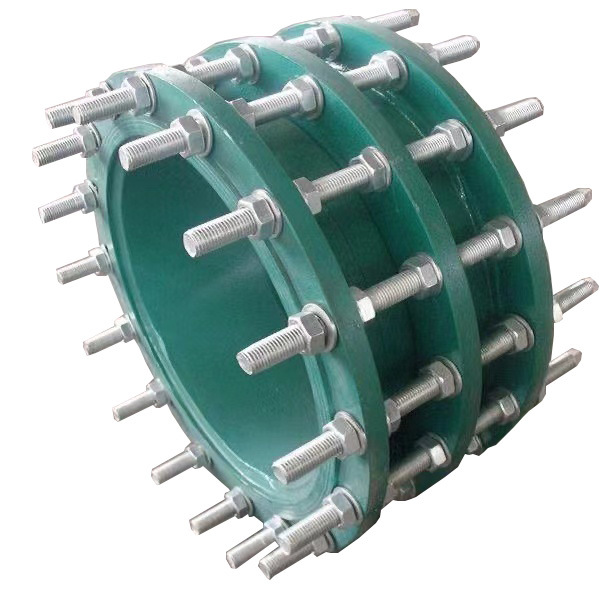

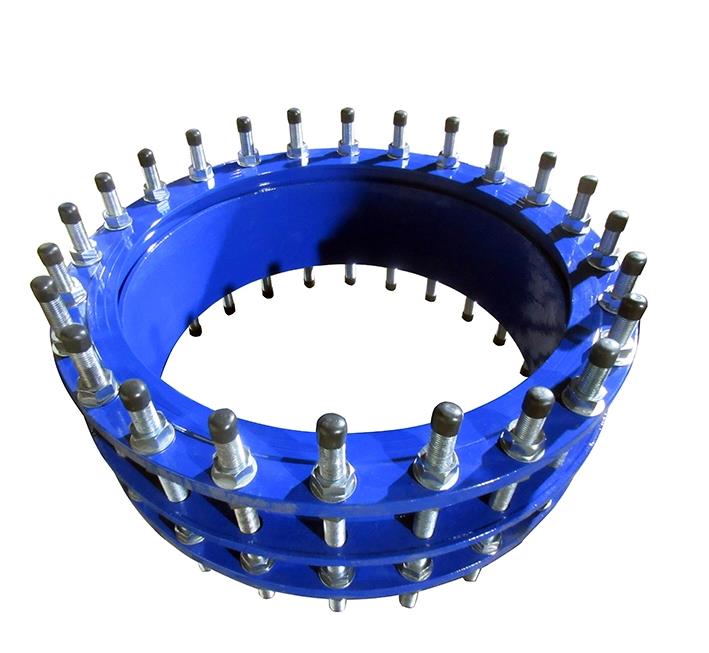

The difference between single and double flanged force transfer joints

We are all familiar with and often see expansion joints and dismantling joints used in equipment in pipelines. Single flange power transmission joints and double flange power transmission joints are two common installation forms of power transmission joints. There are many similarities between th...Read more -

What are the connection methods for dismantling joints?

Dismantling joints, also known as power transmission joints or force transmission joints , are distinguished by single flange power transmission joints, double flange power transmission joints, and dismantling double flange power transmission joints, but their connection methods are not completel...Read more -

Do you know the force transmission joint

The transmission joint is also known as a compensator or flexible expansion joint. It consists of main parts such as the body, sealing ring, gland, and telescopic short pipe. It is a product used for connecting pumps, valves, and other equipment to pipelines. All parts are connected together thro...Read more -

316 stainless steel and 304 stainless steel flange or pipe

In the practical application of equipment pipelines, many products are made of stainless steel or involve stainless steel materials. Although they all belong to stainless steel, there are different types of stainless steel, such as 304 and 316 models. Different models ha...Read more -

What factors affect the use time of clamp expansion joint

When people choose rubber expansion joint, they will have a question: how many years can rubber expansion joint last? What is the usage cycle? Is the frequency of replacement frequent? In fact, there are many factors that affect the service time of rubber flexible joint. Let’s simply list a...Read more