Introduction

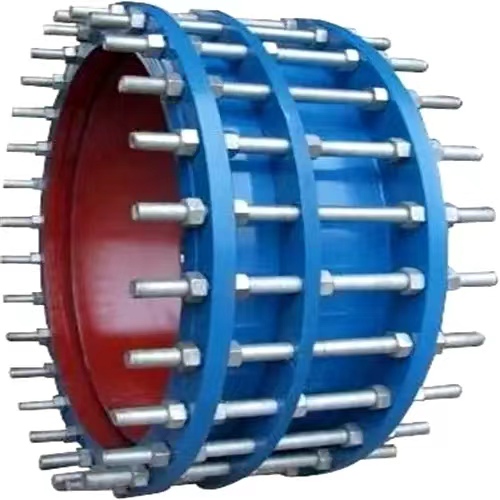

Dismantling Joint refers to the pipeline compensation joint, which is a new product connecting the pump, valve, pipeline and other equipment with the pipeline. It is connected by bolts to make it a whole and has a certain displacement. It is divided into AY type gland expansion joint, AF type flange loose sleeve expansion joint, BF type single flange limit expansion joint, B2F type double flange limit expansion joint, BY type gland loose sleeve limit expansion joint, CF single flange force transmission joint, C2F double-flange power transmission joint, etc.

Definition

The dismantling joint (expansion joint) is mainly used for installation and maintenance. It is adjusted according to the on-site installation size. During operation, the axial thrust can be transmitted back to the entire pipeline system. This not only improves the working efficiency, but also plays a certain role in protecting the pump, valve and other pipeline equipment.

Main materials

QT-400 (nodular cast iron), Q235A (carbon steel), HT20 (gray iron), 304L, 316L (stainless steel)

Installation instructions

Flange type

After the loose sleeve expansion joint is installed on the pipe, tighten the elastic seal ring of the nut. Under the action of the nut gland, the joint is inclined to each other and tightly pressed on the outer ring of the pipe to seal and connect. When the temperature changes, the pipe can expand freely in the middle of the joint. When the foundation sinks, the pipe can deflect and ensure that there is no leakage in the seal, thus achieving the purpose of automatic compensation.

Single flange limit

It is suitable for connecting with flange and welding with pipe at the same time. During installation, adjust the installation length of the product and the pipe or flange at both ends, tighten the gland bolts diagonally and evenly, and then adjust the nuts, so that the pipe can expand freely within the expansion range, lock the expansion amount, and ensure the safe operation of the pipe.

Double flange limit

It is suitable for connecting both sides with flanges. During installation, adjust the connecting length of both ends of the product, tighten the gland bolts diagonally and evenly, and then adjust the limit nuts, so that the pipeline can expand freely, lock the expansion amount, and ensure the safe operation of the pipeline.

Gland type

It is suitable for plugging both sides of the pipe without welding, with reasonable structure, sealing and fast and convenient installation.

Effect

The importance of expansion joints in pipeline installation. Because the temperature of expansion joints connecting expansion pipes or bellows varies greatly, the use of expansion joints is a protective measure. Expansion joints are new products connecting pumps, valves, pipes and other equipment with pipelines. They are connected by full bolts to make them a whole, with a certain amount of displacement, which is convenient for installation. It can withstand the axial pressure of the pipeline. In this way, it can be adjusted according to the on-site installation size during installation and maintenance, which not only improves the working efficiency, but also plays a certain role in protecting the pipeline equipment such as pumps and valves.

Working Principle

The expansion of the pipeline is large, the bearing temperature is high, and the pressure area is strong. In the construction of water supply and drainage works, the foundation concrete pouring or embedded pipes, in the process of these engineering pipes being subject to the building foundation settlement, equipment resonance, geological changes, and changes in the pipeline medium, the pipeline distribution positions begin to be stressed, deformed, twisted and damaged, and the embedded pipes even break, which brings great inconvenience to the construction unit. In order to overcome these difficulties and ensure the safe operation of the pipeline, the use of expansion devices Expansion joint: it can expand and expand axially within a certain range to overcome the displacement, misalignment, expansion and expansion of various angles of the pipeline. The pipe can be freely expanded in the telescopic device. Once the maximum expansion is exceeded, it will play a limiting role. So as to ensure the safe operation of the pipeline!

Post time: Jan-10-2023