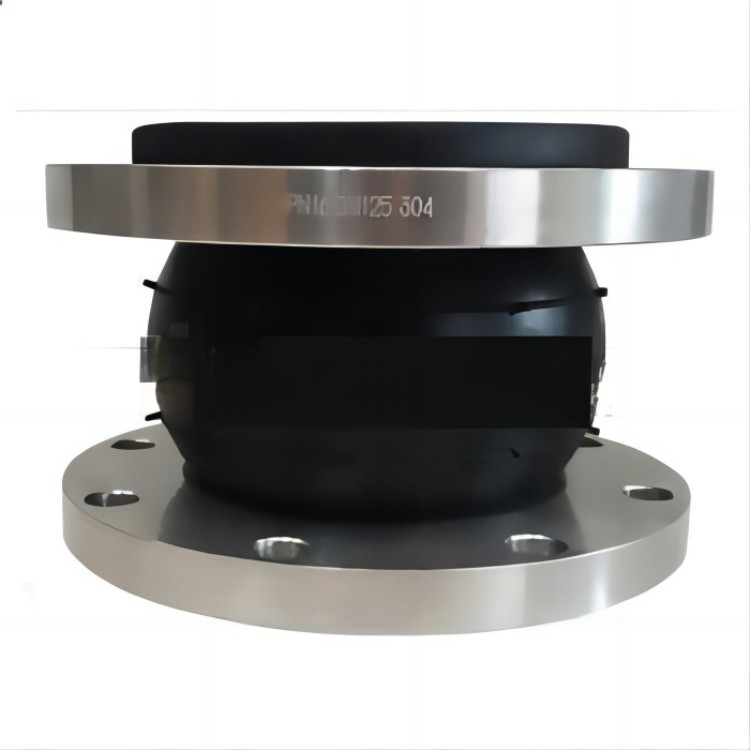

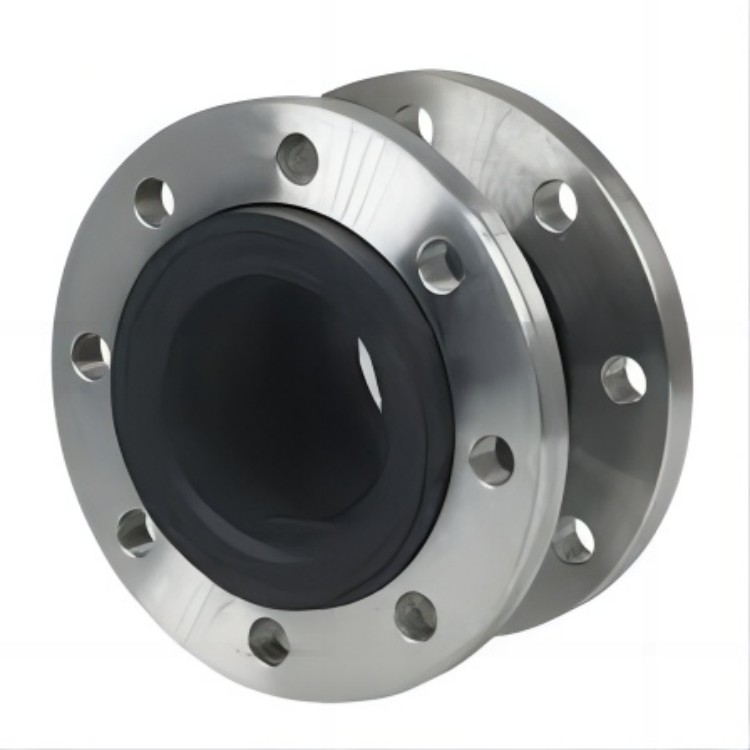

High quality pipe expansion joint

Products Description

Introducing our high quality rubber expansion joints, designed to meet the highest standards of performance and durability. Manufactured with precision and expertise, these expansion joints are an important component in ensuring smooth operation and longevity of your piping system.

Our rubber expansion joints are manufactured from top quality stainless steel material ensuring corrosion and wear resistance, making them suitable for a wide range of industrial applications. These expansion joints comply with ANSI standards and range in size from DN32 to DN3200, designed to meet the diverse needs of customers.

These expansion joints are connected via flanges to provide a safe and reliable connection to the piping system. This ensures a tight seal and prevents leaks, helping to improve the overall efficiency and safety of the system.

Whether it's an industrial, commercial or residential application, our rubber expansion joints provide the perfect solution for accommodating thermal expansion, vibration and misalignment in piping systems. With a focus on precision engineering and quality manufacturing, our expansion joints are built to withstand harsh environments, ensuring long-term reliability and performance.

Main feature

1.One of the main features of our high-quality pipe expansion joints is their construction. Our rubber expansion joints, also known as rubber joints or flexible rubber compensators, are engineered to provide optimal performance. They consist of a tubular rubber component that consists of an inner and outer rubber layer, ensuring durability and flexibility. This structure enables expansion joints to effectively absorb movement, vibration and noise in piping systems, making them an important component in a variety of industrial applications.

2.In addition to their strong construction and resilience, our high-quality pipe expansion joints are designed to provide seamless installation and maintenance. We understand the importance of minimizing downtime and optimizing operating processes, which is why our expansion joints are engineered for easy integration and maintenance. This user-friendly approach not only saves time and resources but also enhances the overall functionality of the piping system.

3.Additionally, our high-quality pipe expansion joints are engineered to withstand challenging environmental conditions. Whether it's extreme temperatures, corrosive substances or high pressures, our expansion joints provide reliable performance in demanding environments. This elasticity not only ensures the longevity of the expansion joints, but also helps improve the overall efficiency and safety of the piping systems into which they are integrated.

Purpose

Connection with pumps, valves and fire-fighting equipment, pipes with large vibration, and pipes with frequent changes in cold and heat.

Applicable media

Seawater, fresh water, cold and hot water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, product oil, air, gas, steam and granular powder.

Advantage

1. Flexibility: High-quality pipe expansion joints can flexibly accommodate axial, lateral and angular movements in the piping system, which helps prevent pipe damage and premature failure.

2. Vibration absorption: These expansion joints can effectively suppress vibrations caused by fluid flow, machinery or external forces, thereby extending the service life of the piping system.

3. Corrosion resistance: When constructed with materials such as stainless steel, high-quality expansion joints exhibit excellent corrosion resistance, making them suitable for a wide range of industrial applications.

4. Easy installation: These expansion joints have standardized specifications and flange and other connection methods, making installation relatively easy, saving time and labor costs in the pipeline system assembly process.

Shortcoming

1. Cost: The initial investment in a high-quality expansion joint may be higher compared to lower-grade alternatives. However, the long-term benefits often outweigh the upfront costs.

2. Maintenance: While high-quality expansion joints are designed to last, they may still require regular inspection and maintenance to ensure optimal performance over time.

Importance

1. In industrial piping systems, the use of high-quality pipe expansion joints is critical to ensuring efficient and safe operation of the system. These expansion joints play a vital role in compensating for thermal expansion, vibration and misalignment in piping systems, thereby preventing damage and ensuring the longevity of the system.

2. A company that has been at the forefront of providing high-quality pipeline expansion joints is located in the Hope New District Industrial Zone, Mengcun Hui Autonomous County, Cangzhou City, Hebei Province, known as the "Elbow Pipe Fittings Capital of China". The company was founded in 2001 and has been committed to manufacturing first-class rubber expansion joints, also known as rubber joints, flexible rubber joints, and rubber compensators.

3. The company's rubber expansion joints are designed to accommodate a variety of media, making them suitable for a variety of industrial applications. The product consists of a tubular rubber component consisting of an inner and outer rubber layer that is flexible and elastic to withstand the needs of different media types. This versatility makes these expansion joints ideal for the petrochemical, water treatment, power generation and other industries.

4. The ability of these expansion joints to effectively handle different media types is a testament to their high quality and reliability. Whether it's corrosive chemicals, abrasive slurries or high-temperature steam, these expansion joints are designed to provide the flexibility and resistance necessary to ensure the integrity of your piping system.

FAQ

Q1. What are the main features of high-quality pipeline expansion joints?

Quality pipe expansion joints are characterized by their durability, flexibility, and ability to withstand high temperatures and corrosive environments. They are designed to provide reliable performance and require minimal maintenance.

Q2. What is the difference between rubber expansion joints and other types of expansion joints?

Rubber expansion joints, also known as rubber joints or flexible rubber compensators, are specifically designed to absorb vibration and movement in piping systems. They consist of inner and outer rubber layers that are highly flexible and effectively reduce noise and impact.

Q3. What are the benefits of using high-quality pipe expansion joints?

By installing high-quality pipe expansion joints, you can effectively extend the life of your piping system, reduce the risk of leaks and failures, and improve overall system performance. Additionally, these joints can help minimize the transmission of noise and vibration, creating a quieter, safer work environment.

Q4. How do I ensure I select the correct pipe expansion joint for my application?

When selecting a piping expansion joint, factors such as operating conditions, pressure and temperature requirements, and the specific needs of the piping system must be considered. Consulting an experienced professional can help you determine which expansion joint is best for your application.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top