GOST 33259 09G2S Mild Carbon Steel CT20 High Pressure Welding Neck Flange DN100 PN100

Product Data

| Product Name | GOST 09G2S High Pressure Welding Neck Flange | ||||||

| Size | 4″ DN100 | ||||||

| Pressure | PN100 | ||||||

| Classification : | Structural steel for welding construct | ||||||

| Density | 7850 kg /m3 | ||||||

| Steel: | 09G2.09G2DT.09G2T.10G25 | ||||||

| Application | Various parts and elements of welded metal structures operating at temperatures from -70 to + 425 ° C | ||||||

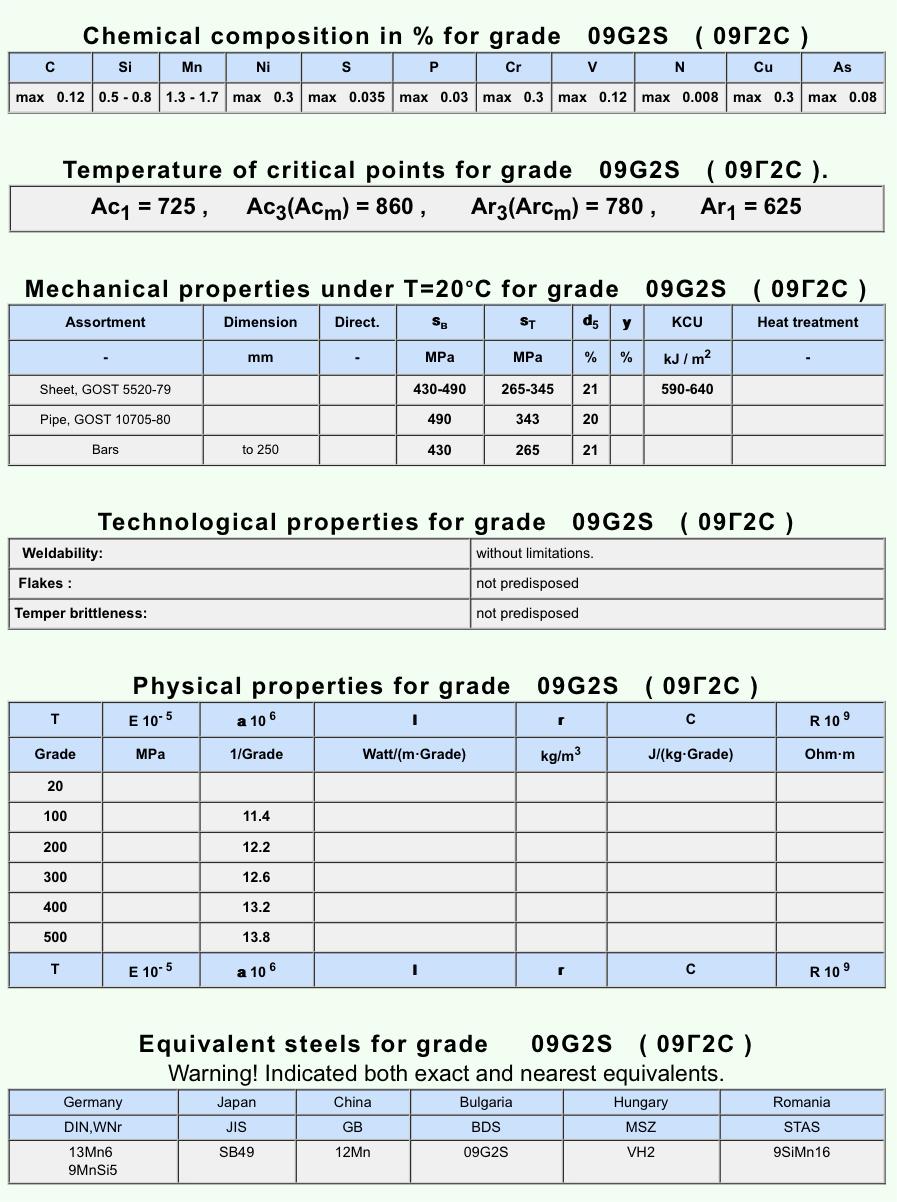

| CHEMICAL COMPOSITION OF 09G2S STEEL | ||||||||||

| C | Si | Mn | Ni | S | P | Cr | V | N | Cu | As |

| max 0.12 | 0.5-0.8 | 1.3-1.7 | max 0.3 | max 0.035 | max 0.03 | max 0.3 | max 0.12 | max0.08 | max 0.3 | max 0.08 |

Product Introduction

The Russian 09G2S standard is a steel standard in the Russian steel standard system. It is also one of the most popular materials in Russia. 09G2S steel is a structural carbon steel, which contains elements including carbon (C), silicon (Si), manganese (Mn), sulfur (S) and phosphorus (P).

09G2S steel has the characteristics of medium carbon content and high strength, suitable for a variety of structural uses, such as construction, Bridges, pipelines, vehicle manufacturing and so on. It has high tensile strength, yield strength and impact toughness, and can withstand large loads and external forces.

According to Russian standards, 09G2S steel needs to meet a series of chemical composition, mechanical properties, metallography and technical requirements. These requirements include the range of carbon content, the range of silicon content, the content of alloying elements, yield strength, elongation, cold bending performance, etc. The purpose of the Russian 09G2S standard is to ensure that steel has the appropriate strength and reliability during use.

09G2S steel is often used in the manufacture of structural components, such as beams, columns and Bridges. It can also be used in the manufacture of high-pressure pipelines, oil and gas transmission lines and mechanical equipment. Its material strength, workability and durability make it a widely used steel.

Weldability :

1.Without limitations- welding is done without heating and subsequent heat treeting

2.Limited weldability-welding is possible under heating up to 100-120 grade and limited weldability subsequent heat treeting

3.Hard weldability-obtaining the quality welding needs the additional operations:heating up to 200-300 grade; the heat treeting ia annealing

High pressure welding neck flange is a fastener used to connect pipes and equipment. It usually consists of two disc-shaped flanges, each with a length of neck with a hole. These flanges are joined by welding the neck of the two flanges together. High pressure butt welded flange with neck is suitable for high pressure and high temperature conditions, with excellent sealing and strength.

Main features:

1. High strength: high pressure neck butt welding flange adopts butt welding connection, can provide high strength and stiffness, adapt to high pressure and high temperature working environment.

2. Good sealing: Through butt welding connection, high pressure butt welding flange with neck can provide better sealing and prevent leakage.

3. Easy installation and maintenance: The high pressure neck butt welding flange is easy to install, just solder the two flanges together, and use bolts to tighten. During maintenance, only the bolt can be removed for maintenance.

4. Wide range of application: high pressure neck butt welding flange is suitable for all kinds of pipeline systems and equipment connection, such as chemical engineering, oil, natural gas, aviation, ships, electric power and other fields.

In short, the high pressure welding neck flange is a fastener used to connect the high pressure and high temperature pipe system, with better sealing, strength and easy installation and maintenance characteristics. It has a wide range of applications in industrial fields.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top