Factory Wholesale Jis 10k Flange - CarbonStainless Steel Plate Flat Welding Flange – Xinqi

Factory Wholesale Jis 10k Flange - CarbonStainless Steel Plate Flat Welding Flange – Xinqi Detail:

Plate Flange

A flange plate is a flat, circular disk that is welded onto the end of a pipe and allows it to be bolted to another pipe. Typically used in fuel and water pipelines, the two flange plates will be bolted together with a gasket in between them. The flange plate will have bolt holes all around the perimeter and will be used to create junctions, tees and joints.

When building a pipeline, the length of the pipes used are not always known. By manufacturing the pipe separate from the flange plate, the welders can cut the pipe to length and weld a flange plate in place to join the pipes at any needed length. The plates can also be welded to the pipe on a slight bias, allowing two pipes to be joined that may not be precisely lined up.

Flange plate designs are uniform in any given size regardless of materials used to create them. This allows a 6-inch (15 cm) black pipe flange to mate perfectly with a 6-inch stainless steel flange. The flange plates will have a serrated finish on the inside mating surface, which allows the plate to seat into the gasket material. This ensures a perfect seal between two joining pipes.

There are many different styles of flange plates that are used for different purposes. The blind plate acts as a cover or cap for a pipe and is used to seal or block off a pipe. The slip-on style of plate allows the plate to be slid onto a pipe and then welded in place. Using the socket weld-style of plate on the ends of two pipes allow them to be easily connected and disconnected.

Flange plates with chamfers and bevels are used to assist in lining up two pipes which are out of alignment. Plates with a studding outlet are plates that have studs inserted around the plate in place of bolt holes. This type of plate allows the pipes to be joined by sliding one flange plate over the studs on a second flange plate and then nuts are tightened to secure the two.

Flange plates make it possible to remove a section of pipe or to add onto a pipeline with ease. Without the flange plates, the pipes would require cutting and welding in order to be separated or added onto. This would be much more expensive and the pipe line would be out of service for a greater length of time.

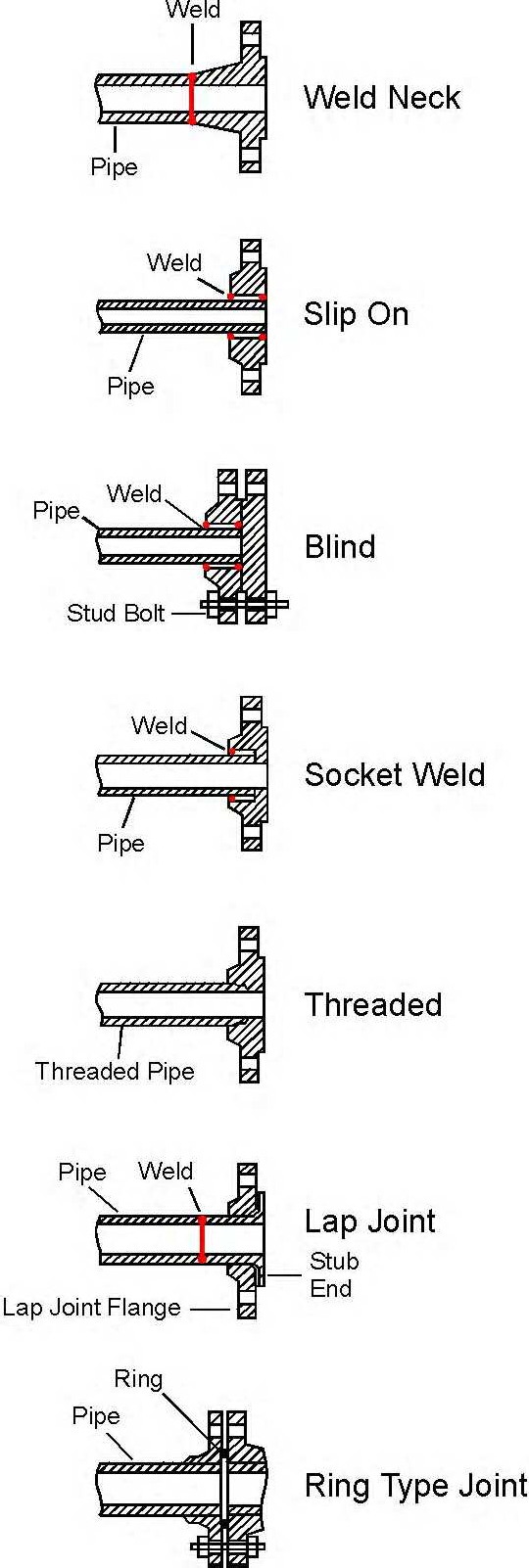

Flange Types

Weld Neck

This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications

erosion inside the pipeline. The weld neck is therefore favoured in critical applications.

Slip-on

This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications.

Blind

This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange.

Socket Weld

This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics.

Threaded

This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required.

Lap Joint

These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel.

Ring Type Joint

This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins during the market competition by its superior quality also as provides extra comprehensive and exceptional service for consumers to let them turn into significant winner. The pursue of the business, is definitely the clients' gratification for Factory Wholesale Jis 10k Flange - CarbonStainless Steel Plate Flat Welding Flange – Xinqi , The product will supply to all over the world, such as: Milan, Malta, Lebanon, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top