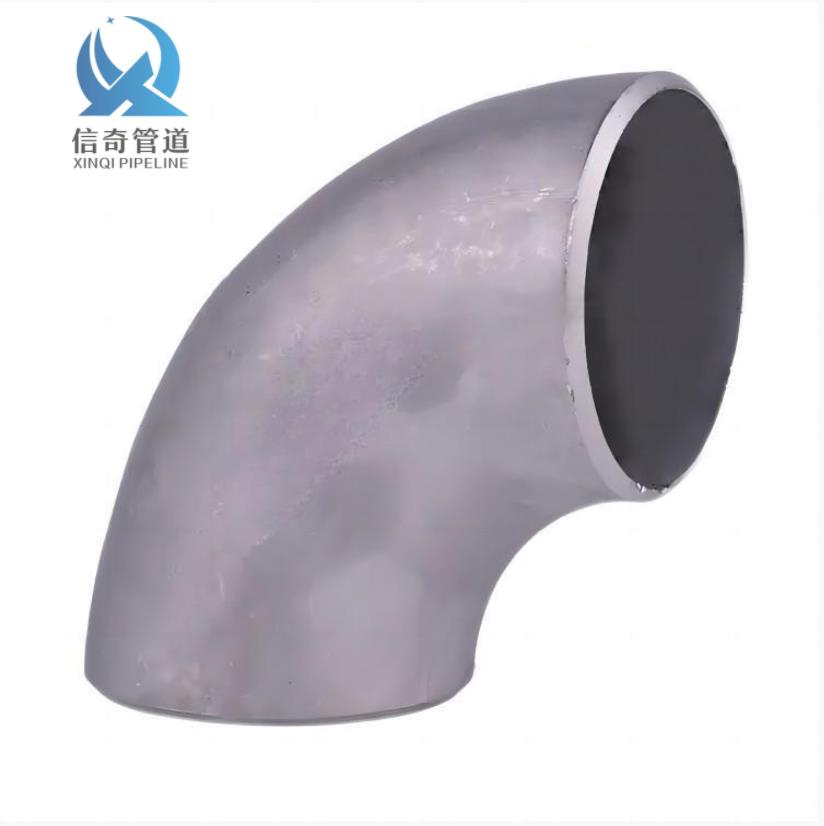

DN900 RF Rubber Lined Expansion Joint

Product Introduction

Size:DN900

Sealing surface:RF

The large-sized rubber expansion joint with protruding surfaces has some unique characteristics and is widely used in various industrial pipeline systems. Here are some of their characteristics, application scope, and advantages and disadvantages:

Features

1. Large size design: suitable for large pipeline systems, capable of handling larger displacements and absorbing more thermal expansion and contraction.

2. Rubber material: Using rubber as the main material, it has excellent elasticity and can effectively absorb vibration and noise.

3. Raised face design: Raised face flange design enables it to connect pipeline systems more flexibly and adapt to displacement in different directions.

4. High temperature and low temperature resistance: able to adapt to a wide range of temperatures, including high and low temperature environments.

5. Waterproof and dustproof: The sealing performance is good, preventing impurities such as moisture and dust from entering the pipeline system.

Application scope

Large size rubber expansion joints with protruding surfaces are widely used in the following fields:

1. Industrial pipeline system: In large-scale pipeline systems in industries such as chemical, petroleum, natural gas, and power, it is used to compensate for pipeline displacement caused by temperature changes and vibration.

2. Water supply and drainage system: In urban water supply and drainage systems, to adapt to the deformation of pipelines under different working conditions.

3. HVAC system: used in large buildings, factories, and other systems to handle thermal expansion and contraction during system operation.

Advantage

1. This expansion joint has a diameter of DN900 and a flange connection. It is suitable for large piping systems where flexibility and movement absorption are crucial. The rubber lining provides superior flexibility for smooth and efficient operation while effectively reducing noise and vibration. This makes it an ideal solution for applications requiring noise and vibration control, such as power plants, chemical plants and HVAC systems.

2. In addition to its flexibility and noise reduction capabilities, the DN900 RF large-diameter rubber-lined expansion joint offers the advantage of ease of installation and maintenance. Its simple yet effective design allows for quick, hassle-free installation, saving time and labor costs. Additionally, expansion joints require low maintenance, helping to save overall costs and extend service life.

3. A manufacturer's commitment to quality and excellence is reflected in the performance and reliability of its products. Large diameter rubber expansion joints are designed and manufactured in compliance with international standards to ensure compliance with industry regulations and requirements.

Disadvantage

1. One of the major disadvantages of DN900 RF large diameter rubber lined expansion joints is their susceptibility to wear. Rubber liners, while designed to provide flexibility and absorb movement in ductwork, can degrade over time, especially when exposed to harsh chemicals, heat, or abrasives. This can result in the expansion joint having a shortened service life and requiring more frequent replacement, resulting in increased maintenance costs for the user.

2. In addition, the large size of the DN900 RF expansion joint can create installation and maintenance challenges. Their weight and size can require specialized equipment and labor, adding to the overall cost and complexity of the project. Additionally, while flange connections provide a secure and leak-free connection, they are also more time-consuming to assemble and disassemble than other types of connections.

Uses

1. Due to their rugged construction and reliable performance, these expansion joints have a variety of use cases. In industrial environments such as chemical plants, refineries and power generation facilities, these expansion joints effectively absorb vibration, reduce noise and compensate for thermal expansion and contraction of piping systems. Their ability to withstand high temperatures and corrosive media makes them suitable for transporting a wide range of fluids and gases in demanding industrial processes.

2. The DN900RF large diameter rubber lined expansion joint is not limited to heavy industry. They are also used in commercial HVAC systems, water treatment plants and infrastructure projects that need to accommodate large pipe and pipe movements.

3. The manufacturer offers flexible sourcing options including OEM/ODM, trading, wholesale and regional agent partnerships. Payment methods such as T/T, L/C and PayPal are supported, ensuring convenience for global customers who wish to integrate these high-quality expansion joints into their projects.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top