DN900 FF Large Diameter Rubber Joint

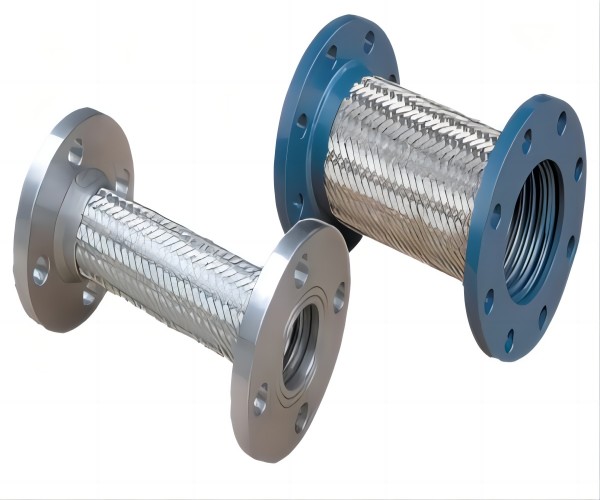

Product Introduction

Size:DN900

Sealing surface:FF

Lined rubber expansion joint is an elastic connector used in pipeline systems, which handles temperature changes, vibration, expansion, and contraction factors in pipelines.

The characteristic of this type of expansion joint is that its inner layer is composed of rubber or rubber like materials, while the outer layer may be made of metal or other materials.

The design of the lined rubber expansion joint aims to provide flexible support while resisting corrosion and temperature changes in the medium.

Key features

1. Rubber inner layer:

The inner layer of the lined rubber expansion joint is usually made of rubber or similar elastic materials, such as Neoprene, Nitrile, natural rubber, etc. This lining material has good elasticity and corrosion resistance, and can effectively absorb vibration and expansion in pipeline systems.

2. Outer layer protection:

The outer layer of the lined rubber expansion joint is usually composed of metal or other reinforcing materials, used to provide structural support, protect the inner layer of rubber, and withstand certain pressure when needed. The selection of outer layer materials usually depends on the application requirements, such as stainless steel, carbon steel, etc.

3. High temperature resistance:

For high-temperature applications, the inner rubber expansion joint may use high-temperature resistant rubber materials to ensure elasticity and performance in high-temperature environments.

4. Scope of application:

This type of expansion joint is usually used to handle vibration, expansion, and contraction in general industrial pipeline systems, such as water supply systems, heating systems, refrigeration systems, etc.

5. Compensation displacement:

The design of the lined rubber expansion joint allows for a certain degree of axial, lateral, and angular displacement to adapt to changes and vibrations in the pipeline system.

Influence factor

Generally speaking, the pressure level of rubber lined expansion joints will consider the following factors:

1.The working pressure of the pipeline system

The pressure level of the rubber lined expansion joint should be able to adapt to the maximum working pressure in the pipeline system to ensure the safety and stability of the system.

2.Characteristics of media

Different media have different fluid properties, such as temperature, corrosiveness, etc. These factors can also affect the selection of lining rubber expansion joints and the determination of pressure levels.

3.Temperature range

The rubber lined expansion joint needs to be able to adapt to temperature changes in the pipeline system. High or low temperature conditions may require the selection of different materials or specially designed lining rubber expansion joints.

4.Flange rating

Rubber lined expansion joints are usually connected to flanges in pipeline systems, and the rating of the flange is also an important consideration.

5.Application environment

Special industrial environments, such as chemical, petroleum, food processing, etc., may have additional requirements for the performance and durability of rubber lined expansion joints.

Influence

First, they can effectively absorb thermal expansion and contraction, reduce vibration and noise, thereby extending the service life of the entire pipe network. This not only minimizes maintenance costs but also improves the overall operational efficiency of industrial facilities.

In addition, the use of lining rubber in expansion joints provides excellent corrosion and wear resistance, making them suitable for a variety of media and operating conditions. This versatility is critical for industries that handle different fluids and gases, where the integrity of the piping system is critical.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top