Chinese Professional Rubber Expansion Joint - Stainless Steel Rubber Bellows Expansion Joints Rubber Connector EPDM – Xinqi

Chinese Professional Rubber Expansion Joint - Stainless Steel Rubber Bellows Expansion Joints Rubber Connector EPDM – Xinqi Detail:

Product Description

Rubber expansion joints are also called rubber joints, flexible rubber joints, flexible rubber compensator, shock absorbers, rubber shock absorbers, etc. The product consists of a tubular rubber part composed of inner and outer rubber layers, cord fabric layers and wire rims, which is vulcanized at high temperature and high pressure and then combined with a metal flange or a loose sleeve of a parallel joint. It can reduce vibration and noise by virtue of high elasticity, high air permeability, medium resistance, weather resistance and radiation resistance of rubber, and can compensate for thermal expansion and cold contraction caused by temperature change. It is widely used in various pipeline systems.

Characteristic:

It has high internal density, can withstand high pressure, and has good elastic deformation effect.

Advantage:

Reduce vibration, noise and lightness.

Purpose:

Connection with pumps, valves and fire-fighting equipment, pipes with large vibration, and pipes with frequent changes in cold and heat.

Applicable media:

Seawater, fresh water, cold and hot water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, product oil, air, gas, steam and granular powder.

Connection mode:

Generally, loose flange type (semi seal), fixed flange type (full seal), clamp type and threaded connection are available.

Material of rubber flexible joint:

The rubber flexible joint ball is composed of a rubber tube with multiple layers of rubber scraped nylon cord fabric and outer rubber layer in the inner rubber layer and reinforcement layer. The rubber materials used are different according to different media, including natural rubber, styrene butadiene rubber, butyl rubber, nitrile rubber, ethylene propylene diene monomer, neoprene rubber, silicone rubber, fluorine rubber, etc. It has the functions of heat resistance, acid resistance, alkali resistance, corrosion resistance, abrasion resistance, oil resistance, etc.

The specific classifications of rubber flexible joints are: Negative pressure resistant rubber joint, acid and alkali resistant rubber joint, oil resistant rubber joint, high temperature resistant rubber joint, wear-resistant rubber head.

Installation of rubber flexible joint:

Rubber expansion joints are widely used in water heating and installation of natural ventilation pipes, water supply and drainage and circulating water pipes, refrigeration pipes, anti-corrosion pipes, fire fighting and refrigeration compressor pipes, as well as in laboratories, scientific research institutions, ships, ships and other pipeline engineering projects to reduce vibration and noise, offset and other maintenance and management methods. The pipe shall be stably suspended in the air water supply and drainage system on the rubber double ball joint on the support, support or anchor frame.

The main characteristics of EPDM rubber expansion joint

1. Aging resistance: EPDM rubber joint has excellent weather resistance, ozone resistance, heat resistance, acid and alkali resistance, water vapor resistance, color stability, electrical performance, oil filling and room temperature fluidity.

2. High temperature resistance: EPDM rubber joint can be used for a long time at 120 ℃, and can be used briefly or intermittently at 150 – 200 ℃. It has excellent water vapor resistance and is estimated to be superior to its heat resistance.

3. Corrosion resistance: due to the lack of polarity and low unsaturation of ethylene propylene rubber in EPDM rubber joints, it has good resistance to various polar chemicals such as alcohol, acid, alkali, oxidant, refrigerant, detergent, animal and vegetable oil, ketone and grease.

4. Good elasticity: EPDM rubber joint is more elastic than natural rubber joint.

EPDM rubber soft connection can reach 150h without breaking under the condition of 50 pphm ozone concentration and 30% stretching, with weather resistance (use temperature range – 40 ℃ – 150 ℃) and chemical resistance. After adding flame retardant, it has good flame retardancy and flame retardancy. The product is processed by microwave continuous vulcanization once, with smooth and beautiful surface, more stable performance( and not easy to change.

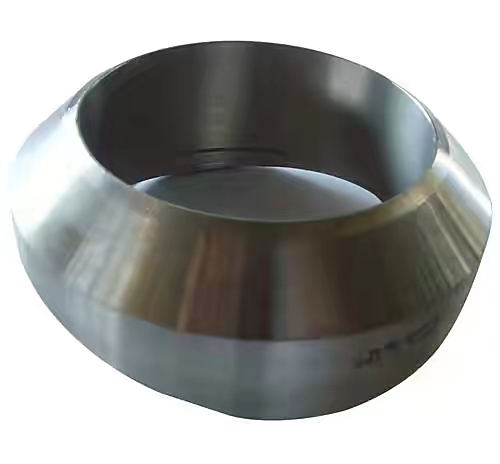

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Chinese Professional Rubber Expansion Joint - Stainless Steel Rubber Bellows Expansion Joints Rubber Connector EPDM – Xinqi , The product will supply to all over the world, such as: venezuela, America, Serbia, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top