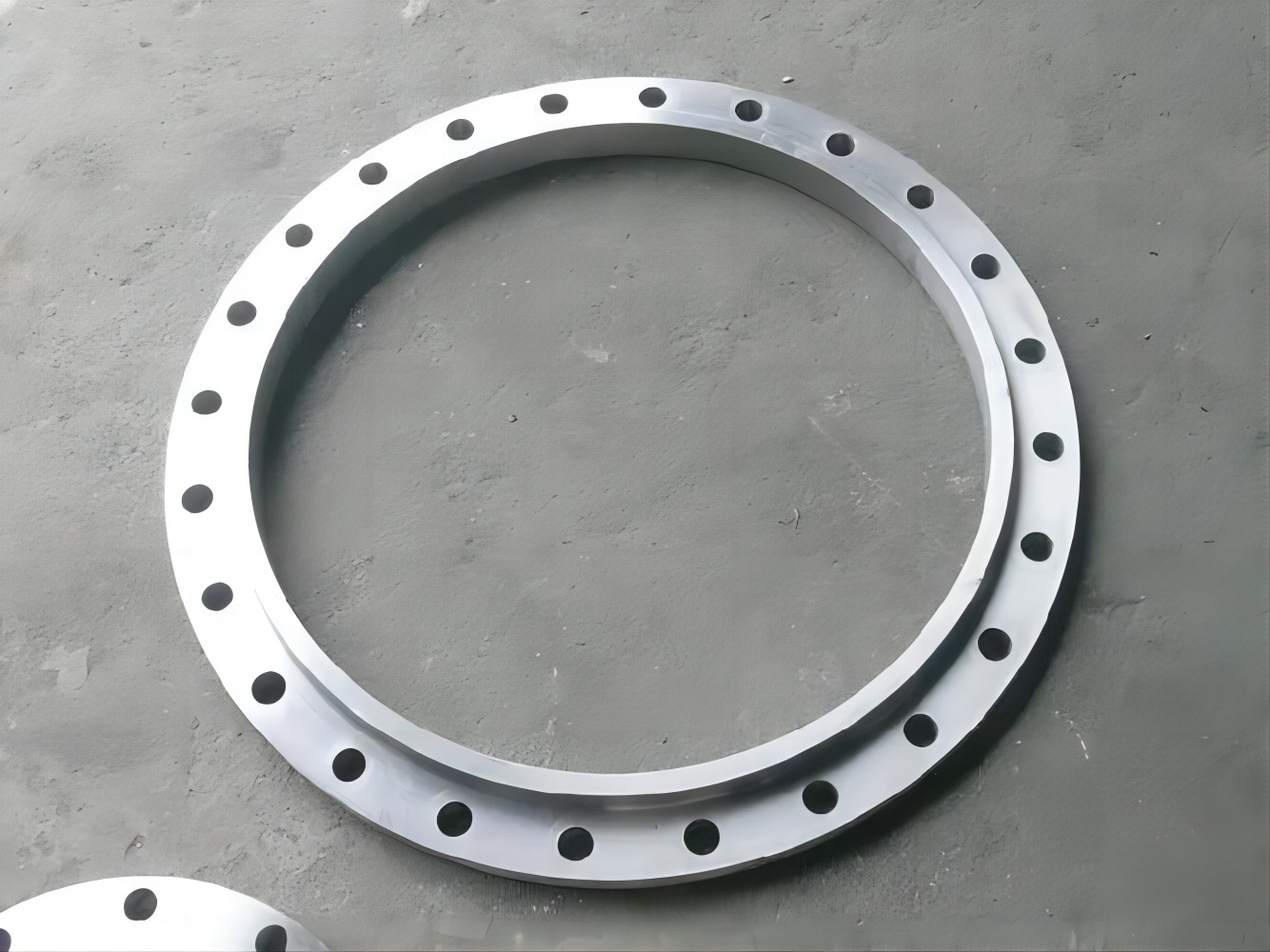

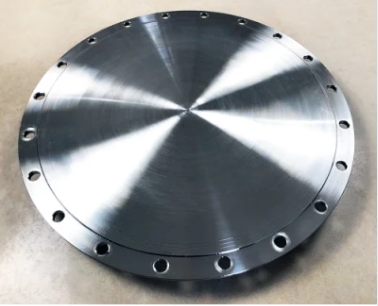

AWWA C207 ASTM A105 Carbon Steel Large diameter Hubbed Slip On Flange

Picture Presentation

Product Data

| Hubbed slip on flange | |||||

| Standard | AWWA C207 | ||||

| Pressure | CLASS D(175-150PSI)、CLASS E(275PSI) | ||||

| Size NPS | 4"-72" DN100-DN1800 | ||||

| Surface | Flat Face, Raised Face,Tongue and Groove, Ring Joint | ||||

| Material | Stainless steel: F304,304L,316,316L,321,A105,A36etc | ||||

| Process Method | Black Painting / Anti Rust Oil / Hot Dip Galvanized | ||||

Product Introduction

AWWA C207 is a standard developed by the American Water Association to regulate the design, manufacturing, testing, and use of neck welded flanges. Neck welded flanges are commonly used in pipeline systems to connect pipes of different sizes or materials, as well as to connect valves, pumps, and other equipment.

The AWWA C207 standard defines various types of neck welded flanges, including specifications of different sizes, pressure ratings, and nominal diameters, to meet the needs of various pipeline systems. The following are common specifications in this standard:

Dimensions:

The AWWA C207 standard includes metric and imperial dimensions, with metric dimensions including DN (DN15 to DN6000) and imperial dimensions including NPS (1/2 "to 144").

Pressure rating:

The AWWA C207 standard specifies multiple pressure ratings, including Class D (175 psi), Class E (275 psi), Class F (300 psi), Class G (300 psi), Class H (300 psi), Class J (300 psi), etc.

Nominal diameter:

The AWWA C207 standard specifies specifications for different nominal diameters, including DN 15 to DN 6000, NPS 1/2 "to 144", etc.

Neck slip on welding flange is a commonly used pipeline connector, suitable for connecting pipes, valves, pumps, and other equipment of different materials or sizes.

Hubbed slip on flange usually consists of two flat flange plates, a neck connecting two flange plates, bolts, and gaskets. Unlike the neck welded flange, the neck welded flange connection requires the use of bolts and gaskets for fixation, rather than through butt welding.

The AWWA C207 standard specifies various types of neck flat welding flanges, including metric and imperial sizes, different pressure ratings, and material grades. For example, the standard specifies six pressure levels: Class D, Class E, Class F, Class G, Class H, and Class J. Among them, Class D is the lowest pressure level suitable for lower working pressures, while Class J is the highest pressure level suitable for higher working pressures.

In addition, the AWWA C207 standard also specifies the manufacturing, quality control, and testing requirements for neck welded flanges to ensure that the produced neck welded flanges meet the standard requirements. When using neck welded flanges, it is necessary to ensure that the material and pressure level of the flange plate and neck are the same, and to install and test according to standard requirements to ensure the safety and reliability of the system. Necked flat welding flanges are commonly used in low-pressure, low-temperature, or low flow pipeline systems, such as water supply, ventilation, air conditioning, and other fields.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top