ASME/ANSI B16.5 Stainless Steel Carbon Steel Welding Neck Flange

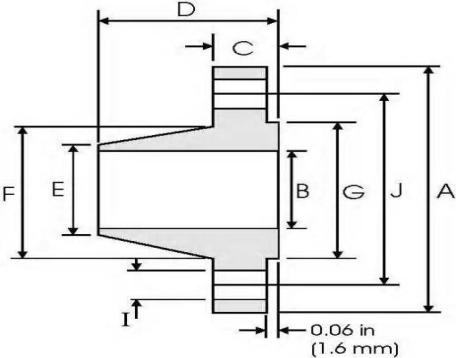

Picture Presentation

Product Data

| Product Name | ANSI B16.5 Welding Neck Flange | ||||||||

| Size | 1/2"-24" DN15-DN600 | ||||||||

| Pressure | Class150lb-Class2500lb | ||||||||

| Numbers of Holes | 4--20 | ||||||||

| Standred | ANSI B16.5 ASME B16.5 | ||||||||

| Technology | Forged,Cast | ||||||||

| Material | Carbon Steel ASTM A105 ST37.0 A350 LF2 A694 F60 A694 F70 | ||||||||

| Stainless Steel SS304 SS321 SS316 | |||||||||

| Sealing Surface | FF、RF、M、FM、T、G、RJ | ||||||||

| Applicable Medium |

oil,gas,water or other medium | ||||||||

| Application | Petrochemical industry;Aviation and aerospace industry;Pharmaceutical industry;Gas exhaust;Power plant;Ship building;Water treatment,etc. | ||||||||

Product Introduction

ASME B16.5 and ANSI B16.5 are standards for steel pipe flanges and flange connections, which are used to specify the requirements for size, design, material and testing of flanges used in piping systems.

ASME is the American Society of Mechanical Engineers standard, and ANSI is the American National Standard, these two standards are actually two versions of the same standard. These are now commonly referred to as ASME/ANSI B16.5 standards

Welding neck flange is also called neck welding flange, which is composed of five parts: neck, flange surface, screw hole, bolt and nut, and sealing gasket. Lan connection device, often used to connect pipes, valves, equipment and other components.

1. Neck: Also known as welding neck, it is a part of the flange, usually composed of a cylindrical neck section, and its shape has two types: long neck and short neck. Choose the appropriate type according to the use requirements.

2. Flange surface: The part connected to the pipe or equipment, usually a flat or raised circular surface.

3. Screw hole: Located on the edge of the flange surface, it is used to install bolts, connect and fix the flange.

4. Bolts and nuts: used to connect and fix the threaded part between two flanges.

5. Sealing gasket: Installed between two flange faces to ensure the sealing performance of the connection.

Features:

1. Excellent sealing performance: The processing of the neck and the structure of the sealing surface can provide reliable sealing performance, which is suitable for high pressure and high temperature environments.

2. Good bearing capacity: The structure of the neck can provide better bearing capacity, making it suitable for high pressure and high load working conditions.

3. Easy to install: the welding connection is stronger, the service life is long, and it is not easy to loosen.

4. Wide application: neck butt welding flange has strong bearing capacity and sealing performance, and is also commonly used in projects with high pressure, high temperature or high sealing requirements. For example, it is often used in petroleum, chemical, natural gas, electric power and other industrial fields.

When using a weld neck flange, it is necessary to place the two flange parts at the connection end of the pipe or equipment to be connected, and then fix them together by welding the neck. During the connection process, the sealing gasket must be installed correctly to ensure that no leakage occurs at the connection.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top