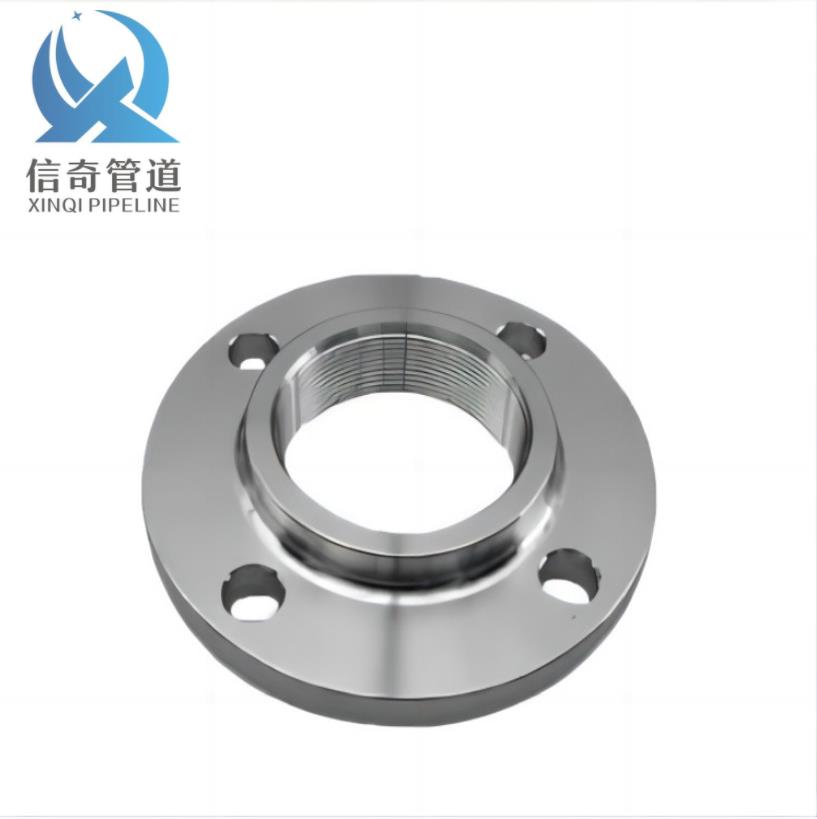

ASME B16.5 Carbon Stainless Steel Lap Joint Flange

Product Introduction

Size

NPS 1/2″-24″ DN15-600

Pressure

Class150-Class2500

Material

Carbon Steel: A105 Q235B S235JR

Stainless Steel: SS304 SS316 SS321

Features:

1. Diversity:

The design of ASME B16.5 loose flange meets the requirements of various sizes and pressure levels, making it suitable for various pipeline systems. This diversity makes it an ideal choice for wide application in different engineering projects.

2. Reliability:

This standard has strict regulations on the design and manufacturing of flanges, ensuring the reliability and stability of connections. This helps prevent leaks and other issues, improving the safety of pipeline systems.

3. Easy to install and maintain:

The design of the loose flange makes it easy to install and disassemble, which is crucial for maintenance and repair work. When maintenance or replacement of parts of the pipeline system is required, loose flanges allow for relatively easy operation.

4. Material selection:

The standard specifies the selectivity of different materials, and suitable materials can be selected according to specific needs, such as carbon steel, alloy steel, stainless steel, etc., to meet the specific environmental requirements of pipeline systems.

5. Compliance with engineering standards:

ASME B16.5 loose flange complies with industry and engineering standards, making it widely recognized internationally.

Application scope:

ASME B16.5 loose flange is widely used in pipeline systems in industries such as petroleum, natural gas, chemical, and power. The main applications include:

1. Chemical industry:

Pipeline systems for chemical plants, refineries, and other chemical facilities.

2. Oil and natural gas industry:

Oil drilling, production and transportation systems, natural gas transmission pipelines, etc.

3. Power industry:

The water supply and cooling systems of power plants, as well as other pipeline systems involving large amounts of water or gas.

4. Manufacturing industry:

Flanges used to connect pipelines and equipment.

5. Aerospace industry:

In aerospace engineering, it involves high-pressure and high-temperature pipeline systems.

Advantages and disadvantages:

Advantages:

1. Standardized design:

The standardized design of ASME B16.5 loose flange makes it easy to be widely adopted, reducing the complexity of design and manufacturing.

2. Easy to install and maintain:

The design of the loose flange simplifies the installation and maintenance process, reducing maintenance costs.

3. Wide applicability:

Due to its diversity, loose flange is suitable for various pipeline systems and meets the requirements of different engineering projects.

4. High reliability:

Loose sleeve flanges that comply with ASME standards usually have high reliability and can provide safe and stable pipeline connections.

Disadvantages:

1. Initial cost:

Compared to some non-standard connection methods, loose flange may have a higher initial cost.

2. Space occupation:

The design of loose flange may take up some additional space, which may not be suitable for some space limited applications.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top