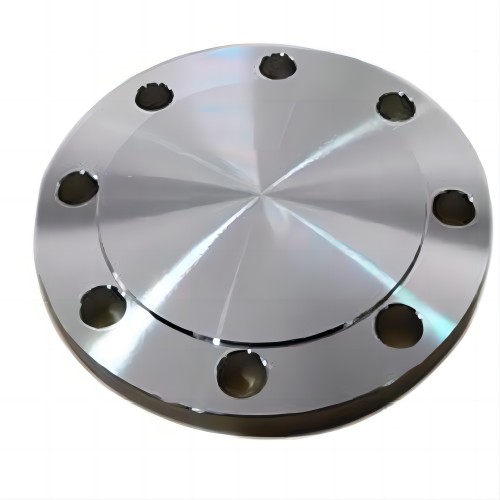

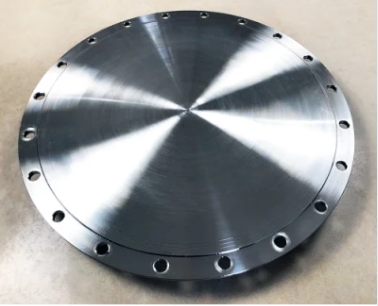

ASME B16.5 Carbon Stainless Steel Blind Blank Flange

Product Introduction

Size

NPS1/2″-24″ DN15-DN1200; NPS1/2″-12″ DN15-DN2500

Pressure

Class150-Class2500

Material

Carbon Steel A105 Q235B A234WPB

Stainless Steel SS304 316 321

Blind flange is a type of flange used in pipeline systems. Its design is relatively simple, usually a blind flange fixed on the flange, which can be fastened to the flange by bolts or other connection methods. Its design is mainly used to seal a diameter on the pipeline, preventing fluid or gas from passing through that diameter.

The blind flange is usually equipped with some connection facilities, such as holes or threads, on the blind flange to facilitate the connection of other equipment or measurement.

ASME B16.5 (American Society of Mechanical Engineers Standard) is one of a set of standards related to pipeline flanges and flange fittings, and ASME B16.5 blind flange is one of them. Here are some basic information about ASME B16.5 blind flange:

The specific selection of blind flange should be determined based on the working pressure of the pipeline system to ensure that the flange can safely and effectively seal the pipeline.

Material:

The manufacturing material of blind flange is similar to other conventional flanges, usually including carbon steel, stainless steel, alloy steel, etc. However, when selecting materials, it is necessary to consider the medium conveyed by the pipeline system and the characteristics of the working environment.

Applicability:

Blind flanges are commonly used for temporary sealing or maintenance work in pipeline systems.

Bolt hole arrangement:

Blind flange usually has a certain arrangement of bolt holes, which is used to tighten the blind flange to the pipeline flange. The number of bolt holes for ASME B16.5 blind flange varies from 4 to 24.

Surface treatment:

According to the standard, the surface treatment of blind flange should comply with the relevant provisions of ASME B16.5 to ensure that the flange has appropriate corrosion resistance and surface flatness during use.

Usage:

Blind flanges are usually used when a section of pipeline in a pipeline system needs to be temporarily closed. This may be due to maintenance, repair, testing, or other reasons that require the temporary closure of a certain pipeline diameter.

When using blind flanges, special attention should be paid to the following points:

1.Before installing and using blind flanges, it is necessary to ensure that the system has been shut down and appropriate safety measures have been taken.

2.The material and sealing performance of blind flange should match the requirements of the pipeline system.

3.Regularly inspect blind flange to ensure its integrity and prevent leakage or other safety hazards.

Overall, blind flange is an important component in pipeline systems, which can effectively seal the pipe diameter and provide flexibility for system maintenance and operation.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top