2022 Latest Design 4 Inch Exhaust Flex Joint - Double Sphere Metal Flexible Joints – Xinqi

2022 Latest Design 4 Inch Exhaust Flex Joint - Double Sphere Metal Flexible Joints – Xinqi Detail:

Product Introduction

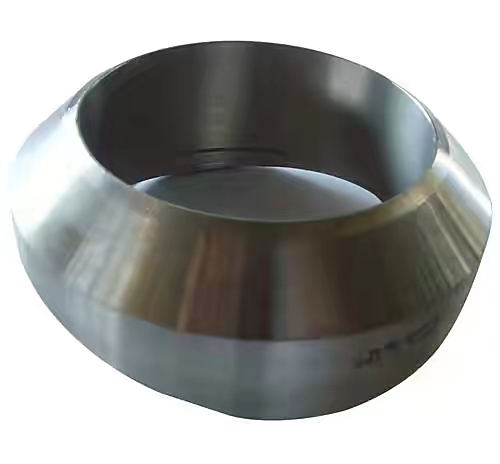

The double ball flexible rubber joint is composed of rubber ball and end flange. The rubber ball is made of natural rubber and nylon cord vulcanization. It can adjust the material of the rubber ball according to the actual environmental conditions of the pipeline, so as to maximize the performance of the rubber joint. The rubber joint industry has been inseparable from the development of the pipeline industry since its emergence. The rubber joint is an inevitable product of the development of the pipeline industry to a certain extent, which also marks that the pipeline industry has entered a new stage.

The flange material of flexible double-ball rubber joint is divided into carbon steel and stainless steel. In terms of pressure bearing performance and corrosion resistance, the stainless steel material should have more advantages, especially for some environments where the installation environment is relatively harsh, such as acid and alkali corrosivity. The stainless steel flange can better reflect its own value, but in general pipeline installation environment, The use of carbon steel flanges is more than enough to fully meet the current pressure environment of rubber joints. After all, stainless steel flanges are 40 percent higher than carbon steel flanges, or even higher.

Effect

The flexible double-sphere rubber joint is installed on the pipeline line to fully and effectively compensate the displacement of the pipeline due to the influence of thermal stress through its own elastic deformation, especially the displacement compensation effect of the rubber joint for long-distance transportation of the pipeline will be more obvious. Secondly, the rubber joint can also effectively alleviate the multi-directional displacement caused by the mechanical vibration of the pipeline, thus improving the stability of the pipeline operation to a certain extent, thus extending the service life of the pipeline.

Performance characteristics

1. Small size, light weight, good elasticity, convenient installation and maintenance.

2. During installation, it can produce horizontal, axial and angular displacement, which is not limited by the fact that the pipeline is not centered and the flange is not parallel.

3. When working, it can reduce the transmission noise of the structure and has strong vibration absorption ability.

Working temperature: – 20 ℃ – 115 ℃

Working pressure: 0.6-2.5MPa

Displacement direction: axial, longitudinal, lateral and angular

Diameter: DN32-DN1000

The common flexible double ball rubber joint is used for conveying air, compressed air, water, sea water, oil, acid, alkali, etc. at 15 ℃~115 ℃. The special flexible double-ball rubber joint is used to transport the above media or oil, concentrated acid, alkali and solid materials above 30 ℃~250 ℃.Flexible double-ball rubber joint can be widely used in water supply and drainage, circulating water, HVAC, paper making, petrochemical, ship, compressor, water pump, fan and other pipeline systems.

Advantage

Because of its excellent elasticity and ductility, the double-sphere flexible rubber joint is widely used in various pipeline compensation, especially for the displacement settlement compensation and noise absorption of long-distance pipelines of large-diameter circulating water pipes in power plants. The inner layer of flexible rubber joint is made of high-quality nylon lotus seed cloth and rubber joint skeleton layer welded with hard steel wire, which has very good compressive strength to ensure that the rubber joint is not easy to be pulled and torn in the process of application, and can be restored to normal after reducing the deformation. The high wear resistance of nylon cord fabric is the guarantee of rubber joint ductility, while the lifting layer of steel wire ring is the guarantee of rubber joint compressive strength.

The dual-sphere flexible rubber joint is specially designed with patented lifting collar according to the application situation reflected by the customer, which has very good impact resistance and ensures the stability of the weak part of the rubber joint. Especially when it is applied in the high pressure above, it is necessary to modify the secondary equipment.

Application

It is also suitable for our factory’s flexible rubber joint in the desulfurization tower because it is made of EPDM high wear-resistant rubber with strong corrosion resistance and also has certain corrosion resistance. Therefore, the compensation for the lime slurry pipeline has a significant role and is widely used in the desulfurization tower. The double-ball flexible rubber joint is refitted at the water pump mouth, which has remarkable shock absorption and noise reduction effect and ensures the tightness of the pipeline.

Because the rubber flexible joint absorbs the vibration of the pipeline, it can prevent the pipeline bolt from falling down due to vibration. Therefore, the flexible rubber joint is a very good choice for shock absorption and noise reduction to compensate for displacement and settlement. Flexible rubber flexible joints are widely used in power plants, chemical industry and municipal engineering. When maintenance personnel are running a plant pipeline transportation system, if they find that there are small cracks or material leakage on the pipeline surface of the pipeline transportation system, they need to replace the pipeline or flexible rubber joints immediately, When this kind of situation occurs in the pipeline transportation system of high pressure or corrosive substances, it is necessary to be concerned and vigilant about the aspect ratio to prevent the generation of danger.

In the mechanical and chemical industries, the characteristics of flexible rubber joints and the quality of raw materials determine whether the pipeline transportation system can be used for a long time. When the flexible rubber joint works in a long-term displacement natural environment, the polymer formula of the rubber will be destroyed, and the flexible rubber joint will be destroyed. At this time, the flexible rubber joint needs to be replaced in time.

Data Details

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for 2022 Latest Design 4 Inch Exhaust Flex Joint - Double Sphere Metal Flexible Joints – Xinqi , The product will supply to all over the world, such as: Liberia, Myanmar, Azerbaijan, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top