2022 China New Design Stainless Exhaust Bellows - Socket Welding Cross – Xinqi

2022 China New Design Stainless Exhaust Bellows - Socket Welding Cross – Xinqi Detail:

Product introduction:

Socket welding pipe fittings are made by inserting stainless steel pipe into the socket of the pipe fitting and pushing it to the location step of the socket, and conducting a circular argon shielded welding along the contact between the socket end of the pipe fitting and the outer wall of the pipe. Welding wire is not required (instead of the socket end of the pipe fitting), which belongs to a “joint free connection” pipe connection mode.

The socket cross is composed of a socket, a socket, a bending part, a socket, etc., which is characterized in that there is a socket on the socket, and the socket and the socket are respectively located at both ends of the bending part. In a piping system, a socket cross is a fitting that changes the direction of a pipe run.

Texture of material:

The materials of socket welding cross include cast iron, stainless steel, alloy steel, castable iron, carbon steel, nonferrous metals and plastics.

The main manufacturing standards generally include GB/T14383, ASME B16.11 and BS3799.

Scope of application:

Socket couplings can be widely used for pipes of different diameters, including single, three-way, four-way, etc., as well as water meters and valves. Because of the use of socket structure, the cost of pipe joints is reduced, and the installation, use and maintenance are very convenient. At the same time, the pipe joints have extremely high leak proof capacity, which has a great market prospect.

Size range:

DN6-DN100

Pressure rating:

3000 lb, 6000 lb, 9000 lb

| Socket Weld Pressure Class | Pipe Schedule | ||||

| Class 3000 | S80/XH | ||||

| Class 6000 | S160 | ||||

| Class 9000 | XXH |

Data Reference

| Socket Weld Elbow Specification: | |||||

| Size | 1/8″~4″ (DN6~DN100) | ||||

| Class | 3000 LBS, 6000 LBS, 9000 LBS | ||||

| Type | Socket weld | ||||

| Surface Treatment | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Soldering | ||||

| Materal | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel | ||||

| Manufacturing process | Cutting, Heat treatment, Forging, Machining | ||||

| Manufacturing Standards | ASME 16.11, GB/T14383-2018,BS-3799 | ||||

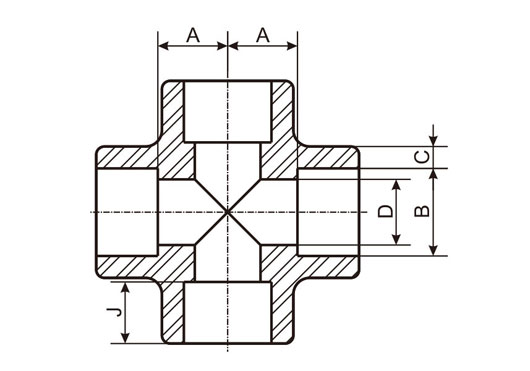

| DN | Nom.Pipe Size | Center to Bottom of Socket-A | Socket Bore Dia.B | Bore Dia.Of Fitting D | Socket Wall Thickness(2) C | Body Wall Thickness G | Depth of Socket Min.J | ||||||||||||||

| 90°Elbows Tees,Crosses | 45°Elbows | Class Designation | Class Designation | ||||||||||||||||||

| Class Designation | Class Designation | Class Designation | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Ave. | Min. | Ave. | Min. | Ave. | Min. | Min. | Min. | Min. | ||||

| 6 | 1/8″ | 11 | 11 | — | 8 | 8 | — | 10.8 | 6.9 | 4 | — | 3.18 | 3.18 | 3.96 | 3.43 | — | — | 2.41 | 3.15 | — | 9.5 |

| 8 | 1/4″ | 11 | 13.5 | — | 8 | 8 | — | 14.2 | 9.3 | 6.4 | — | 3.78 | 3.3 | 4.6 | 4.01 | — | — | 3.02 | 3.68 | — | 9.5 |

| 10 | 3/8″ | 13.5 | 15.5 | — | 8 | 11 | — | 17.6 | 12.6 | 9.2 | — | 4.01 | 3.5 | 5.03 | 4.37 | — | — | 3.2 | 4.01 | — | 9.5 |

| 15 | 1/2″ | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 | 21.8 | 15.8 | 11.8 | 6.4 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 |

| 20 | 3/4″ | 19 | 22.5 | 28.5 | 13 | 14 | 19 | 27.2 | 21 | 15.6 | 11.1 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 |

| 25 | 1″ | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 | 33.9 | 26.7 | 20.7 | 15.2 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 |

| 32 | 1-1/4″ | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 | 42.7 | 35.1 | 29.5 | 22.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 |

| 40 | 1-1/2″ | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 | 48.8 | 40.9 | 34 | 28 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 |

| 50 | 2″ | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 | 61.2 | 52.5 | 42.9 | 38.2 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 |

| 65 | 2-1/2″ | 41 | — | — | 28.5 | — | — | 73.9 | 62.7 | — | — | 8.76 | 7.67 | — | — | — | — | 7.01 | — | — | 16 |

| 80 | 3″ | 57 | — | — | 32 | — | — | 89.8 | 78 | — | — | 9.52 | 8.3 | — | — | — | — | 7.62 | — | — | 16 |

| 100 | 4″ | 66.5 | — | — | 41 | — | — | 115.2 | 102.3 | — | — | 10.69 | 9.35 | — | — | — | — | 8.56 | — | — | 16 |

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for 2022 China New Design Stainless Exhaust Bellows - Socket Welding Cross – Xinqi , The product will supply to all over the world, such as: Southampton, Portugal, Greek, Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top